Palletizing solution

Designed to meet the specific requirements of palletizing, you'll enjoy peace of mind when you install and use the low-risk Robotiq Palletizing Solution. The solutions are based on best practice and have been extensively tested, guaranteeing reliability and a rapid return on investment.

The palletizing solution is designed to make automation accessible. Whatever your expertise in robotics, you can master your robot with confidence. Using a Robotiq palletizing solution is as easy as using a tablet.

Turnkey

Simplifies the installation process and starts working immediately.

Hassle-free

Integrates into existing systems without conversion work.

Evolutionary

Adapts to variable product lines and guarantees long-term operations.

User-friendly

Allows all types of users to operate with ease and confidence.

Adaptability

Easily adapts to your production schedule. No need to stop your production line for hours.

Deployment

Thanks to perfect compatibility between components, the solution takes up little space and adapts to your existing installations.

No external PC required.

Ingenious

Optimizes robot movements without programming.

Return on investment (ROI)

Security

Standardized

Built on best practices and thoroughly tested to guarantee reliability.

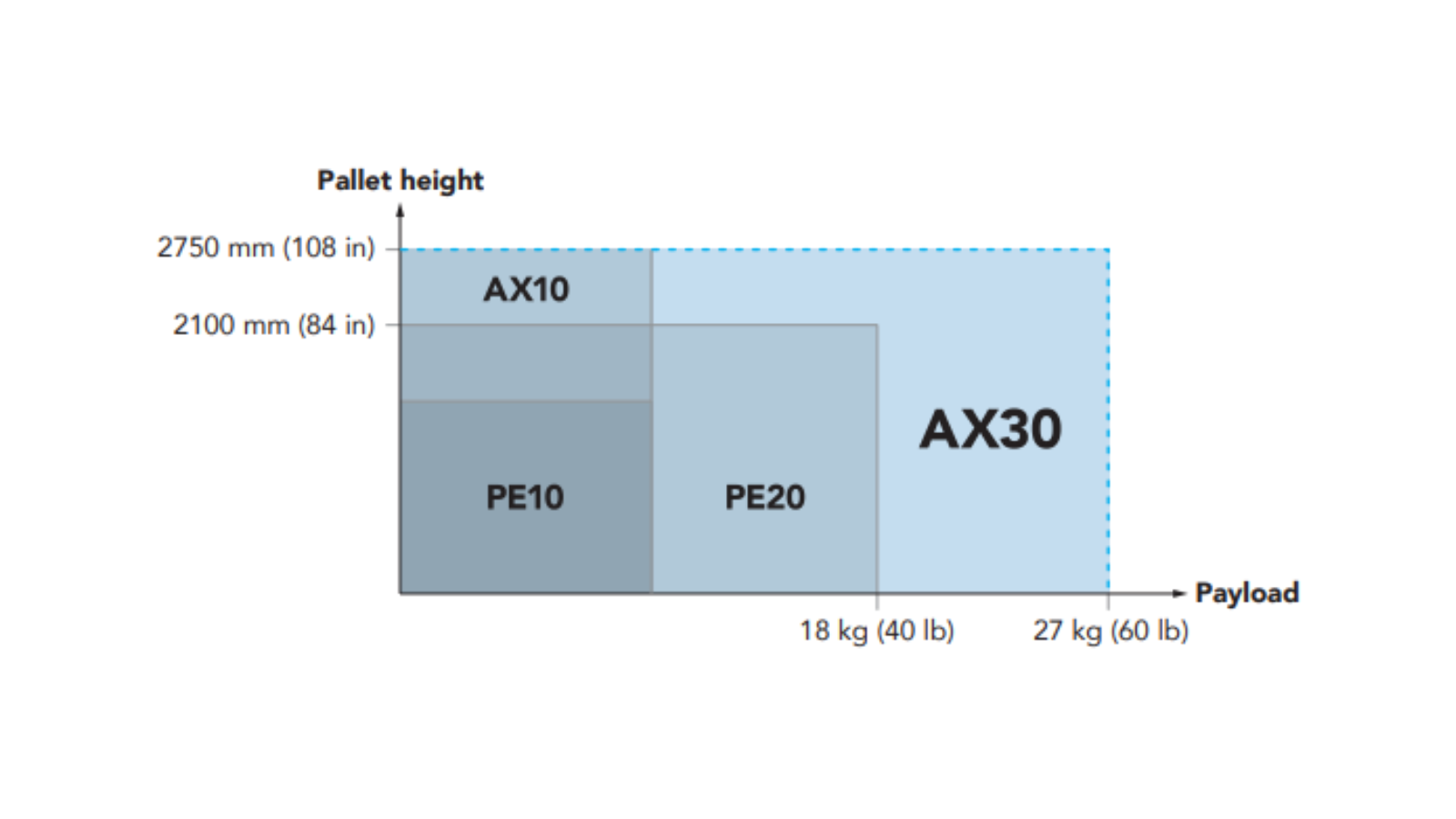

Choosing the right solution requires consideration of factors such as daily palletizing volume, production line capacity, case weights, pallet heights and available space. Robotiq offers a range of palletizing solutions, ensuring that there's an option to suit your needs.

Payload: Up to 11.5kg (25lbs)

Pallet height: up to 155cm (60in)

Throughput: up to 13 cycles/min

Ideal for less frequent changes of box size and pallet height.

Payload: Up to 18kg (40lbs)

Pallet height: up to 215cm (84in)

Throughput: up to 13 cycles/min

Ideal for heavier loads and moderate pallet heights.

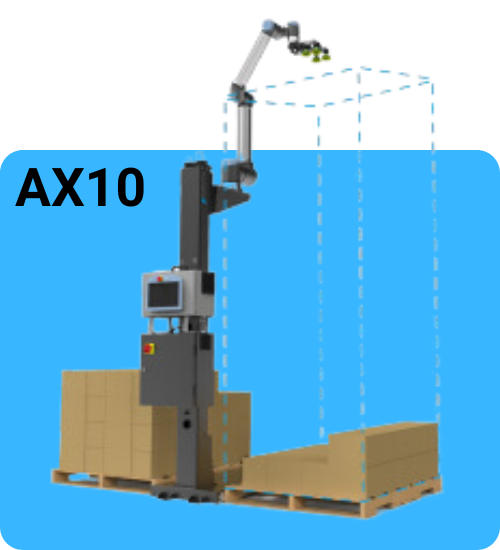

Payload: Up to 11.5kg (25lbs)

Pallet height: up to 275cm (108in)

Throughput: up to 13 cycles/min

Ideal for handling a wide range of pallet heights and light loads.

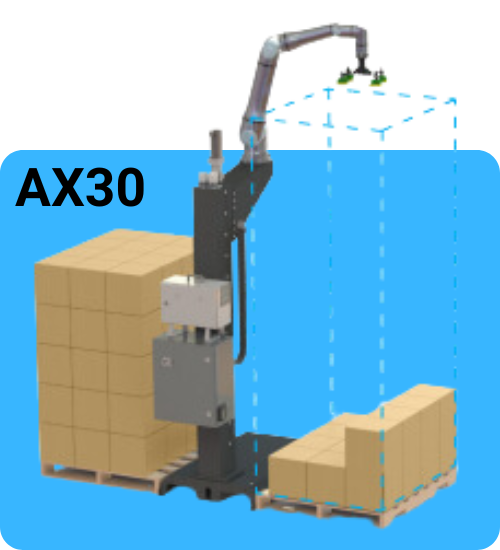

Payload: Up to 27kg (60lbs)

Pallet height: up to 275cm (108in)

Throughput: up to 13 cycles/min

Ideal for stacking heavy boxes and buckets at different heights.

Setting up your job is simple and requires just three steps

#1 Box specification

#2 Pallet dimensions

#3 Palette configuration

Robotiq Palletizing Solutions

- Flexibility and adaptability: Robotiq palletizing systems are designed to be flexible and adaptable to a variety of production environments. They can be easily reprogrammed for new palletizing patterns, making them ideal for companies with variable production requirements.

- Ease of integration: One of the major advantages of Robotiq solutions is their ease of integration into existing production lines. They are compatible with a wide range of industrial robots, enabling seamless integration and reducing downtime.

- Intuitive user interface: Robotiq makes a point of making its systems accessible, even to operators with no previous robotics experience. User interfaces are designed to be intuitive, simplifying programming and handling of palletizing systems.

- Space optimization: Robotiq solutions are designed to maximize the use of factory space. Their compact design allows them to be integrated into tight spaces, optimizing available production space.

- Improved productivity and safety: By automating the palletizing process, Robotiq solutions reduce the manual workload, minimizing human error and improving workplace safety. This translates into increased productivity and reduced costs associated with injuries and worker fatigue.