TAWI - A Piab Group brand

Since January 2020, TAWI has been part of the Piab Group.

Piab is a world leader in lifting, gripping and moving solutions for the automated world. They help our customers grow by providing intelligent products and solutions that transform their businesses through increased automation.

TAWI knows that time is money

With a TAWI system, you have a wide and varied range of handling aids, for all kinds of components and parts needed to feed your production line, in the most efficient way possible, while significantly reducing or even eliminating the need for hydraulic lifting systems, or stackers, and the maintenance obligations associated with their use, or breakdowns. All in one! A TAWI system offers you lower costs, speed and flexibility, and guarantees the possibility of modification to adapt to changing procedures, as well as unrivalled safety.

The sectors of activity

Our customers operate in almost every sector, includingfood, automotive, logistics, e-commerce and pharmaceuticals. TAWI works to create and innovate for the progress and technological evolution of ergonomic lifting, automation and robotics.

Industries worldwide benefit from the TAWI approach. Their solutions guarantee safe and efficient material handling, wherever you are. Here are just some of the industries that benefit from TAWI products.

Automotive

Ergonomic lifting solutions to reduce the high number of occupational injuries associated with handling components or packages in the automotive sector.

- Incoming goods

- Assembly line

- Handling components and parts

- Handling in storage areas

More information

Efficient handling of incoming goods

Producing a car is a complex process. A car can be made up of parts from over 4,000 different suppliers. All these elements have to be stored on a single site. This wide range of components and parts arrives by road or rail, and has to be unloaded and stored at a single production site. The parts used for the chassis are delivered to one area, while those for the bodywork to another. The repetitive movements involved in handling these components demand physical effort, and are an essential and time-consuming part of the process.

Simplify the assembly line

During assembly operations on automotive assembly lines, speed and precision are the keys to profitability. Lifting equipment on assembly lines must facilitate work flow as much as possible, and ensure that parts are handled safely. Lifting must be extremely precise and safe, so that assembly line operators can work precisely and safely.

Faster, safer handling of components and parts

The many components and parts that make up a modern automobile don't come to life in a boardroom. Manufacturing these components is a complex and demanding process. TAWI lifting solutions can help ensure maximum efficiency and safety at every stage of the manufacturing process, from the production and manufacture of individual parts and modules to the final assembly of these components into the finished automobile.

TAWI's wide range of vacuum lifting solutions enables automakers and their suppliers to manage the movement, lifting and placement of components faster and more reliably than ever before.

In the right place at the right time

Car parts are often bulky or irregular in shape, making them unsuitable for conventional storage - and conventional lifting solutions. TAWI's range of vacuum lifting devices makes it easy to store and retrieve these parts, from exhaust pipes to windshields, batteries to component boxes - handling them is easier than ever. A TAWI system can be customized to suit any storage operation, providing a space-saving, ergonomic and easy-to-use solution.

Chemical

Ergonomic lifting solutions to reduce the high number of occupational injuries associated with handling in the chemical industry.

- Filling and weighing

- Chemical treatment

- Palletizing chemical products

More information

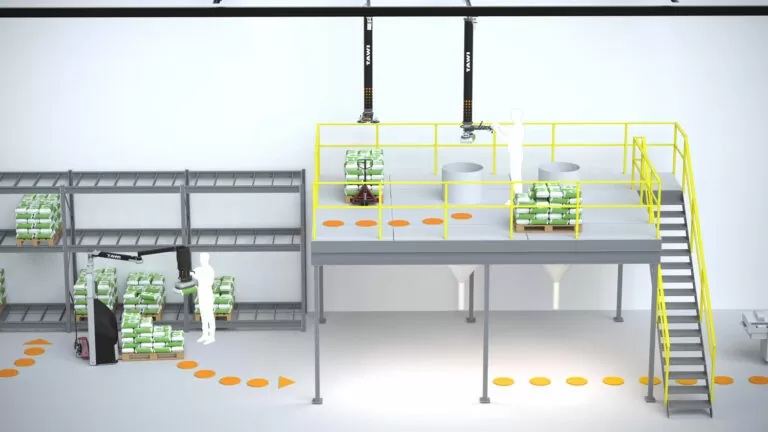

Eliminate the weakest link to boost process efficiency

When filling or weighing ingredients or chemical components, it is essential that nothing compromises the packaging or the process so as to avoid contamination. When trying to increase efficiency at this stage of the process by reducing manual lifting and handling, it is essential that the lifting equipment used guarantees the integrity of the product or packaging, while eliminating the risk of musculoskeletal disorders (MSD).

Balance without sacrifice

Materials used in the chemical industry generally arrive at the plant in paper or plastic bags and sacks (sometimes in drums or cans). The size and fragility of these types of packaging present a whole range of handling challenges. Often quite heavy and easily torn, these bags are difficult to lift and handle ergonomically. Lifting and holding these heavy bags while opening and emptying the contents can even be difficult for two people working together, and carries a high risk of product contamination.

Maximum efficiency - maximum safety

In the past, palletizing was generally a laborious manual process. This led to frequent musculoskeletal disorders, work stoppages and damage to products or ingredients. A TAWI system, equipped with their vacuum lifting devices, cleanroom products or ATEX-certified solutions, enables many types of packaging, as well as the most flammable or sensitive ingredients, to be packed or palletized safely and efficiently.

Logistics

TAWI supplies some of the world's most innovative lifting solutions for logistics, including vacuum lifting systems, stackers, crane systems, hoists and gripping tools. The creation of an optimal logistics flow ranges from sorting, packaging and order picking to palletizing/de-palletizing.

- Unloading containers and trucks

- From conveyor to pallet

- Order preparation

More information

Efficient container unloading

Unloading cartons from containers? Allow your staff to reach each carton and lift it ergonomically, from the top to the bottom of the container, without losing pace. Handling heavier goods such as large bags or car tires? No problem.

With mobile vacuum lifting systems, anyone can handle heavy goods, and lifting 80 kg will seem easy.

Flexible parcel handling for efficient logistics operations

As one of the world's fastest-growing industries, the logistics industry faces a number of challenges. The steady increase in online shopping offers great potential, but also brings with it pressure to deliver goods ever faster and more reliably. The modern online shopper expects goods to be delivered quickly and without damage. Logistics centers need to speed up their workflows while improving their reliability.

Economical and efficient order picking

The challenge of ergonomic and efficient order picking in warehouses is a constant battle for many companies. Often, a variety of goods with different weights and shapes have to be selected, requiring a flexible and simple lifting device. Check out this guide to efficient order picking to find out more.

Another challenge when using elevator systems for order picking is to be able to reach all the objects on a pallet, from top to bottom and from inside to outside points. TAWI's latest lifting innovation, theEasy Reach tool , makes this possible.

Food industry

Ergonomic lifting solutions to reduce the high number of occupational injuries associated with the handling of unpackaged or packaged raw materials in the food industry.

Solutions for every stage of operations in the food and beverage industries:

- Receipt of food raw materials

- Food industry

- Packaging and palletizing

More information

Efficient handling of incoming goods

The manufacture of products in the food and beverage industry encompasses a wide range of ingredients and packaging. Whether it's drums of liquids or oils, or bags of powders or cereals, all these ingredients have one thing in common: they come from one place and have to be moved to another. A TAWI solution helps ensure that, whatever materials are used in your manufacturing process, you can handle them quickly, safely and with minimum effort.

Hygiene in the food process

The raw materials that go to make up our food and beverage products come in many different types of packaging, from cans and cartons to bags, rolls, tubes and more. Handling this diverse range of packaging safely and hygienically is a constant challenge. With TAWI's stainless steel lifting systems, you can meet this challenge, lifting almost any type, regardless of gripping surface or volume, safely and in compliance with sanitary standards. TAWI vacuum grippers can handle plastic, paper and jute bags, boxes and cartons, drums and barrels, and crates of all types.

Risk management in the food industry

When packing or palletizing ingredients or raw materials for food and beverage products, any tears or holes in the bags could allow foreign substances to infiltrate the products, damaging them and rendering them unfit for consumption.

TAWI's range ofvacuum lifting equipment eliminates this danger and increases process productivity, by enabling the most fragile containers or packaging to be moved, stacked or handled without risking damage to products or employees.

Pharmaceuticals

Ergonomic lifting solutions to reduce the high number of occupational injuries associated with handling raw materials or finished products in the pharmaceutical industry.

- Weighing in the pharmaceutical industry

- Processing of pharmaceutical products

- Pharmaceutical packaging

More information

Weighing and distribution

The weighing room is the gateway to manufacturing and an important transition point for materials arriving from a warehouse and entering the processing area. Handling at this stage of the process is crucial to ensure continuous manufacturing. By paying particular attention to the layout, equipment and operations in the weighing room, you set the stage for an efficient manufacturing process.

- PHARMA Safe and ergonomic weighing

- stainless steel and ATEX lifting tools

- Improved ergonomics and safety

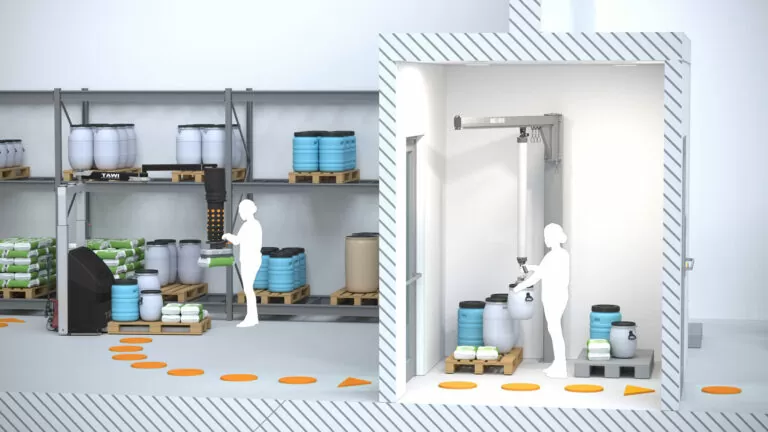

Safe handling in the pharmaceutical industry

The manufacture of pharmaceutical products is a sensitive process, not least because of the delicate handling of APIs (Active Pharmaceutical Ingredients) and raw materials, which must not be contaminated under any circumstances. To maintain a safe environment, production processes often take place in protected cleanrooms. Cleanrooms are designed to maintain extremely low levels of particles such as dust, airborne organisms or vaporized particles. All equipment used in cleanrooms must be designed to minimize air contamination and be very easy to clean.

Cost-effective, flawless handling of pharmaceutical products

The pharmaceutical industry is a sensitive environment, leaving no room for errors, whether in production or packaging. Every stage of pharmaceutical production and packaging is closely monitored and governed by strict sanitary rules. Uniformity, cleanliness and sterility are among the prerogatives standardized to guarantee good manufacturing practices. But in a competitive and constantly evolving industry, efficiency and continuity of productivity are of paramount importance. To maintain an uninterrupted, efficient workflow in terms of production and packaging, a reliable lifting system is a must.

Wood and steel

Ergonomic lifting solutions to reduce the high number of occupational injuries associated with handling large boards and panels in the wood and steel industries.

- Efficient handling and palletizing

- Wood, metal and glass handling

- CNC machine loading - numerical control system

More information

Easy, economical palletizing

Palletizing boards and panels often requires the operator to tip the boards between horizontal and vertical positions, a difficult and tiring movement if performed without lifting aids. Investing in lifting tools designed to streamline this process can quickly become a source of increased productivity and reduced overall costs.

Reduce lost time and work-related accidents

Efficient, risk-free handling of heavy loads can be achieved with lifting equipment tailored to your needs. TAWI offers not only high-quality solutions, but also comprehensive service and maintenance contracts to support your operations and reduce the risk of unnecessary equipment downtime.

- Save money with TAWI solutions

- Reduce production downtime and injuries

- Efficient materials handling

CNC machine loading - Profitability

Lifting, transporting and positioning large, heavy plates or components requiring the intervention of several people is time-consuming and costly in terms of procedures.

A lifting system for handling, loading and unloading is a worthwhile investment that will bring rapid returns on operations.

- Cost-effective CNC loading/unloading

- Save time and increase operator safety

- Reduce employee injuries and equipment damage

Airport and Ports

Solutions ergonomic lifting solutions to reduce the high number of occupational injuries associated with baggage handling.

- Luggage handling

- Moving, loading and unloading luggage

- Handling baggage selected for screening

- Air cargo handling

More information

Lifting luggage from carousels or conveyor belts

The TAWI baggage lift is the ultimate solution for transferring baggage between baggage conveyors or carousels and AKEs and/or open carts.

Powered by an electric pump, the TAWI vacuum lifter becomes a flexible, ergonomic and durable extension of the user's arm. It can also easily lift cardboard and metal boxes, backpacks and luggage. TAWI vacuum lifting equipment helps airport and port handlers to become more efficient and ergonomic.

Checked baggage handling

At many airports, checked-in baggage is automatically transported and conveyed to chutes by the airport's sortation system. Baggage is then transferred from the chutes to carts, where it is transported to the aircraft. The area where baggage is transferred from the chutes to the carts is generally characterized by low ceilings, and sometimes also by limited working space.

For port departures, luggage is usually transferred from a conveyor belt to open carts, which are then transported to the cruise ship.

Checked baggage reconciliation area

At airports, suspect baggage is directed from the Explosives Detection System to a Baggage Clearing Area (CBRA), where it must be lifted and moved from a conveyor belt to an inspection station. After inspection, the security agent must place the baggage on the conveyor belt towards the exit. Before TAWI's solutions for CBRA rooms, these tasks were performed manually, resulting in injuries and reduced productivity.

CBRA rooms are often airport-specific. Reduced heights, tight spaces and working around pillars require extremely flexible lifting solutions. TAWI's vacuum lifting equipment, specially developed for CBRA halls, makes it possible to lift and transfer baggage in confined spaces, while avoiding injury and increasing productivity.

Loading and unloading air freight at airports

Air freight is transported all over the world in cargo aircraft, usually loaded with loading units (ULDs) or containers and pallets. Before the freight is loaded onto the aircraft, it has to be sorted and loaded into a ULD, an operation which also includes the transfer of air freight between pallets and open containers.

After the aircraft has been unloaded, the cargo must be unloaded from the ULDs and transferred to the appropriate load-carrying devices for the next transport within the airport. These loading, unloading and sorting processes are often carried out simultaneously, resulting in musculoskeletal disorders due to repetitive strain, reduced productivity and increased sick leave.

Need help with your project?

TAWI products

Thanks to innovative Swedish engineering, TAWI lifting solutions have created a working environment where every employee can lift loads, increasing productivity and safeguarding employee health. Effective lifting ensures safe and efficient handling, whatever the load.

Most manufacturing industries, logistics centers and other companies handling light products have much to gain from implementing a lifting device in their workflow. Manufacturing industries often use TAWI electric mini-stackers to place coils in packaging machines or to transport finished products off the production line.

TAWI vacuum cups and hoists are frequently used to lift raw materials such as wood or metal, food ingredients and raw materials, or chemicals. They are also of interest to industries with high lifting rates, a recurrent phenomenon at the end of production lines, in packaging or during palletizing.

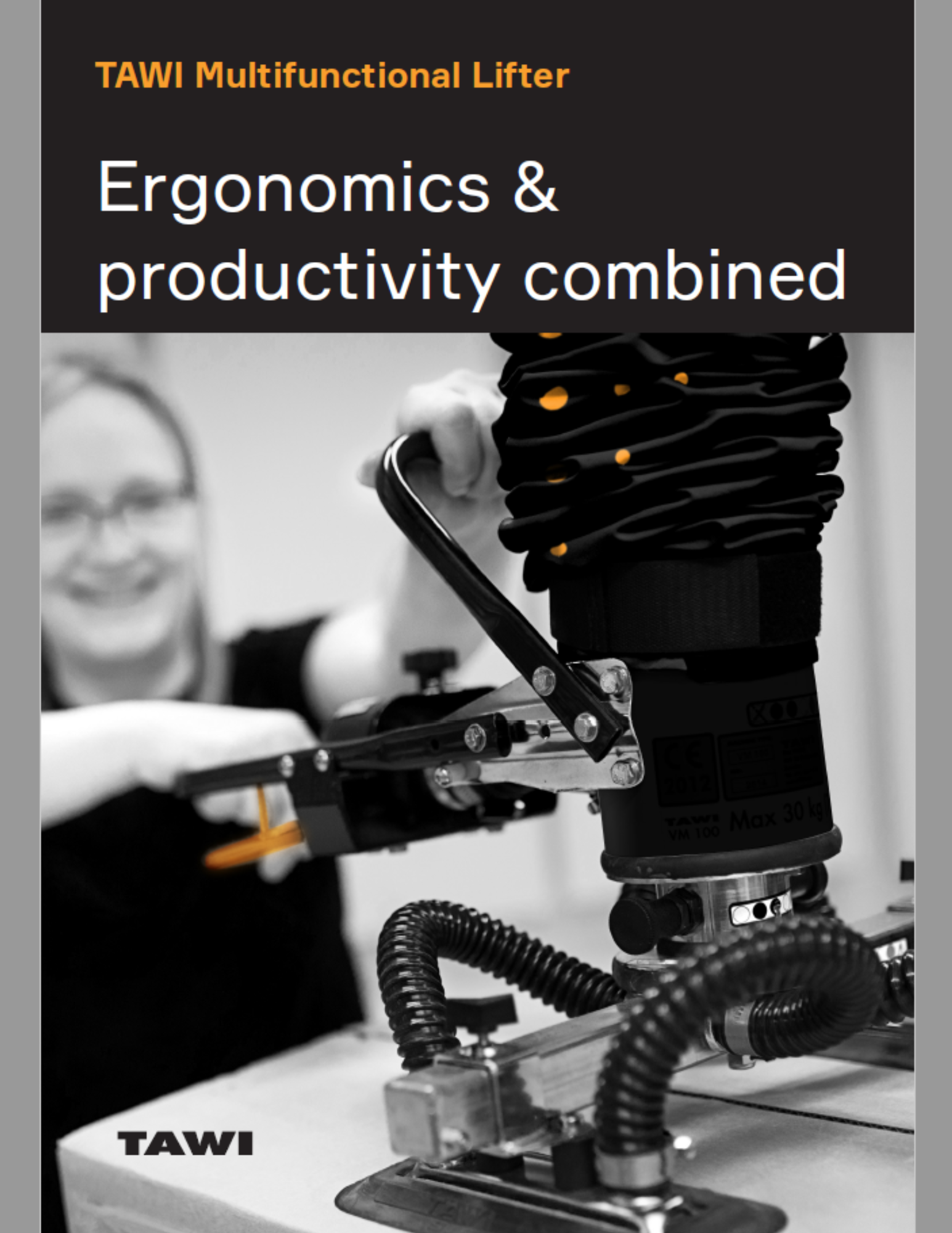

Vacuumlifter

Vacuum lifting systems use the power of vacuum to grip and lift the load. Vacuum technology ensures safe, efficient and durable handling of most products using vacuum cups.

- Ergonomic and safe for operators.

- Gripping without risk to the load.

- Lifting with the best cost-efficiency ratio.

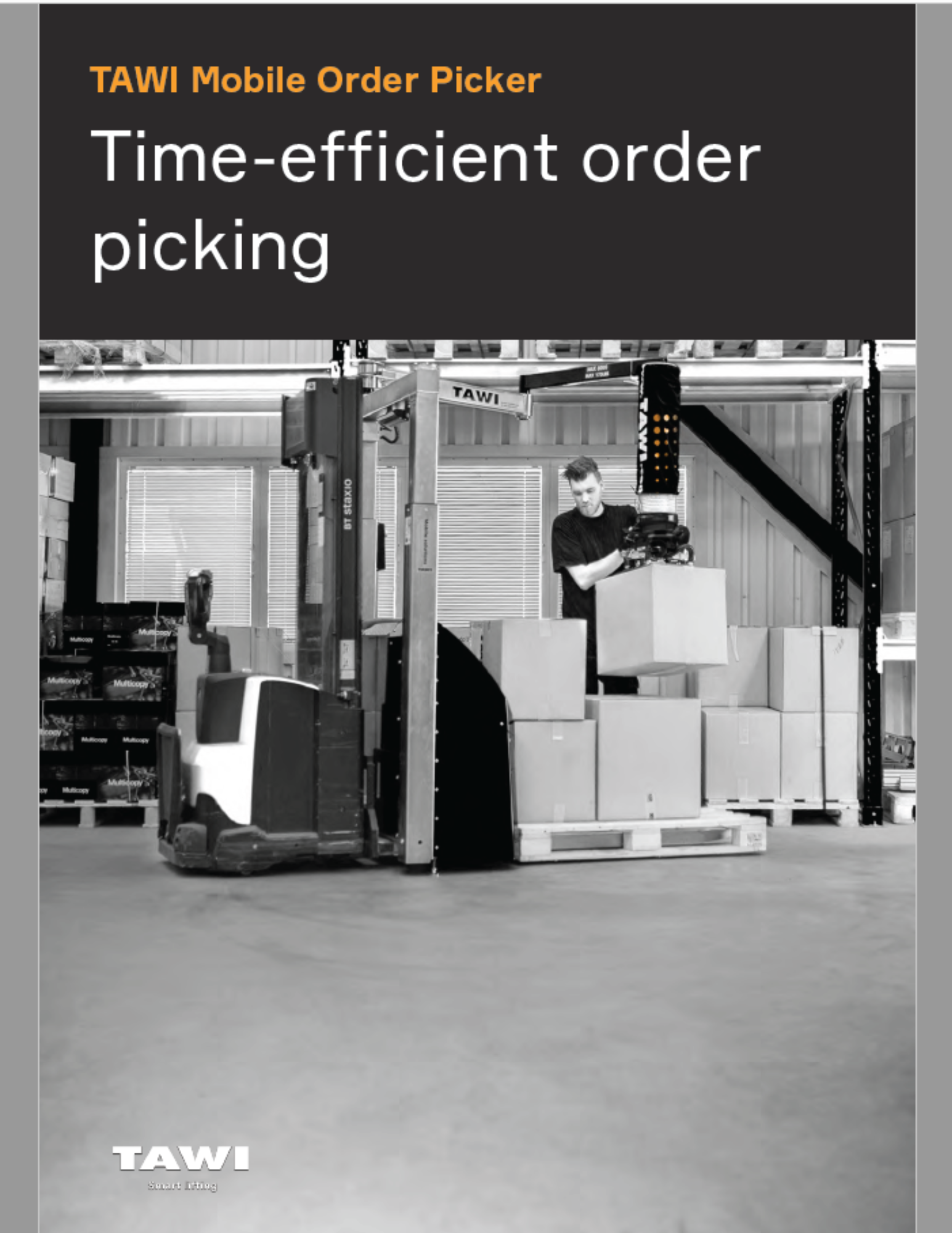

Mobile vacuum lifting system

The TAWI mobile order picker offers a unique solution for efficient materials handling.

- Mobile unit compatible with all electric forklifts and pallet trucks.

- Perfect for fast-paced order picking and general warehouse handling.

- Effortless pallet picking.

- Unlimited reach in pallet racking and other tight spaces.

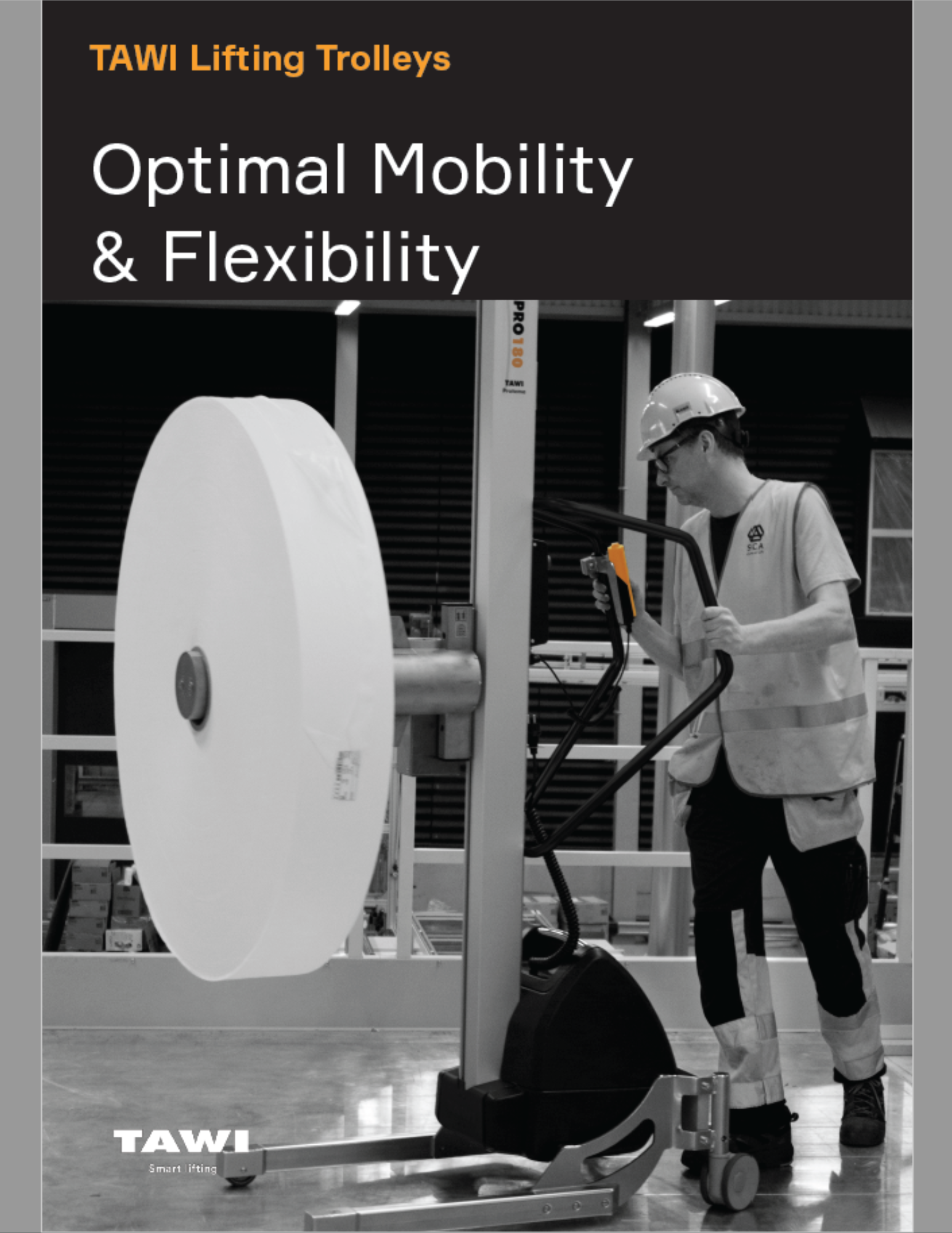

Electric stackers(lifting trolleys) and forklifts

Our electric stackers are robust and easy to use. Their height, width and load capacity can be adjusted to suit your needs.

- Wide range of tools for different load types

- Easy-to-use and ergonomic, they relieve users of tedious manual handling.

- All-stainless steel versions available for easy cleaning

- Lift and move wherever you want thanks to our mobile devices

Customized gantries, bridges and jib cranes(crane)

TAWI suspension systems are tailored to the needs of each company, guaranteeing optimum suspension of lifting accessories for smooth operation in all industries.

- Steel and aluminum sections

- Tailor-made structures for your facility

- Moveable gallows for maximum mobility.

Hoists and gripping tools for easy handling

Our wire rope hoists are faster than most in their class, and offer optimum lifting accuracy for delicate operations. For lifting heavy loads, or difficult applications, we offer durable, high-capacity chain hoists.

- Precise lifting thanks to variable speed drive

- Simple, one-handed operation

- Gripping tools for all types of loads

Lifting for all

All TAWI lifts are designed for optimum user comfort, making lifting easy for everyone, whatever their job. TAWI modifies its products for customers, ensuring that your TAWI elevator always meets your needs, thus increasing your company's productivity.

Industry-specific requirements and individual operator needs are taken into account in the development of solutions, ensuring that the system is easy to use and does not interfere with your business requirements.

The Company TAWI

Swedish inventors since 1923

2023 marks the 100th anniversary of the TAWI brand. As it celebrates its 100th anniversary, the company has over 600 employees in almost 100 countries around the world.

The strength of TAWI lies in their knowledge in-depth and experience in development innovative solutions, their motivated sales team and a reliable service and installation process for all TAWI solutions. This winning formula is only made possible by trust and a spirit of collaboration, the true catalysts of the company's success.

Some TAWI catalogs

Our aim is to help our customers get the most out of their products by helping them reduce total costs. TAWI's product data sheets are designed to give you the technical information you need to select the right product(s) for your business.

Electric stackers

Optimum mobility and flexibility

Order picker

Efficient order picking

Versatile lifting tube manipulator

Combining ergonomics and productivity

Our team remains at your disposal to discuss your automation project. Do not hesitate to contact us.

Address

100 Goyer Street, room 103

La Prairie (QC)

J5R 5G5

Phone

514.745.1987

1.800.361.1684

info@pneumac.qc.ca