Our products Piab

Piab, specializing in automated process components and solutions to enable gripping, lifting and moving applications, takes automation to the next level by creating sustainable solutions for a safer, more efficient workplace in an automated world.

They provide gripping skills for robots, intelligent flow to materials and lifting power for humans.

Our customers are in all sectors, includingfood and beverage,automotive,packaging, logistics and warehousing, e-commerce,electronics, chemicals and pharmaceuticals, and general manufacturing.

Vacuum pumps and ejectors

Piab vacuum pumps/vacuum generators are primarily based on patented COAX® technology. COAX® technology is an advanced solution for creating vacuum with compressed air. Based on Piab's multi-stage technology, COAX® cartridges are smaller, more efficient and more reliable than traditional vacuum ejectors, making it easy to design flexible, modular and effective vacuum systems. A vacuum generator based on COAX® technology delivers three times the suction rate of a conventional system, enabling higher speeds to be achieved while maintaining high reliability and reducing energy consumption.

Suction pads and flexible grippers

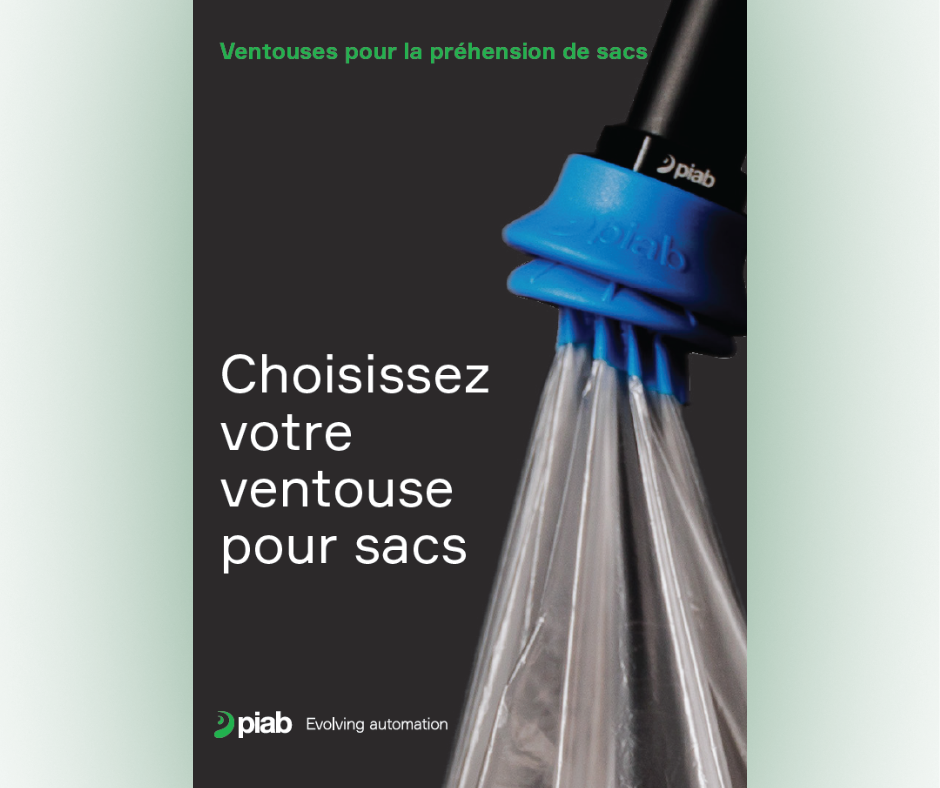

Suction cups and flexible grippers offer endless possibilities for your lifting and gripping needs. You can, for example, handle materials, cartons or foodstuffs, even open bags, pick up electronic components, label and hold objects. However, in different applications, you need to meet different needs and requirements. Piab offers one of the widest ranges of suction pads on the market, with a solution for every application. Tell us what you need, and we'll help you find the right solution and products.

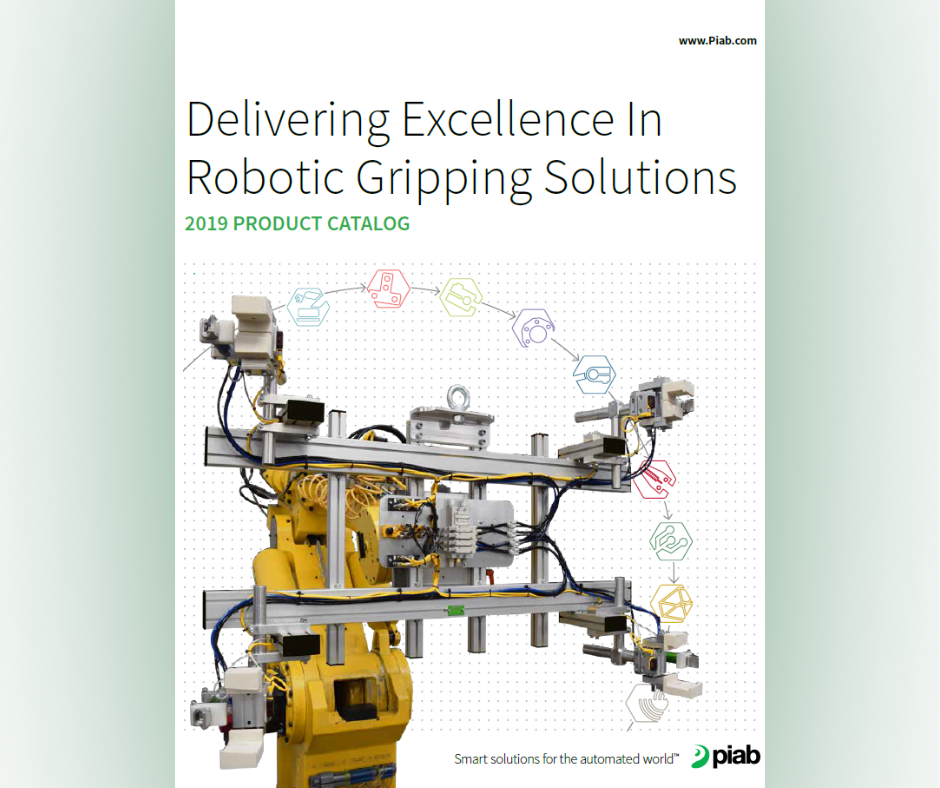

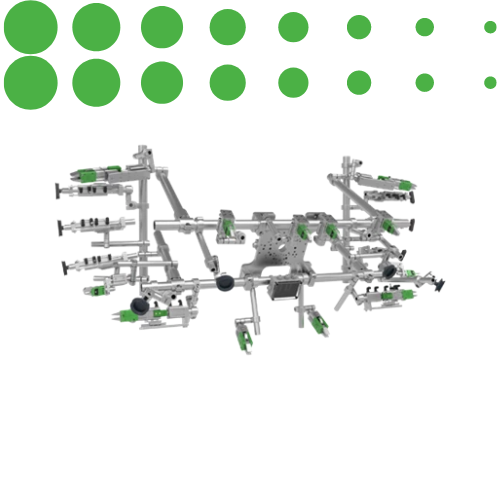

Components for robotic hand grippers (EOAT)

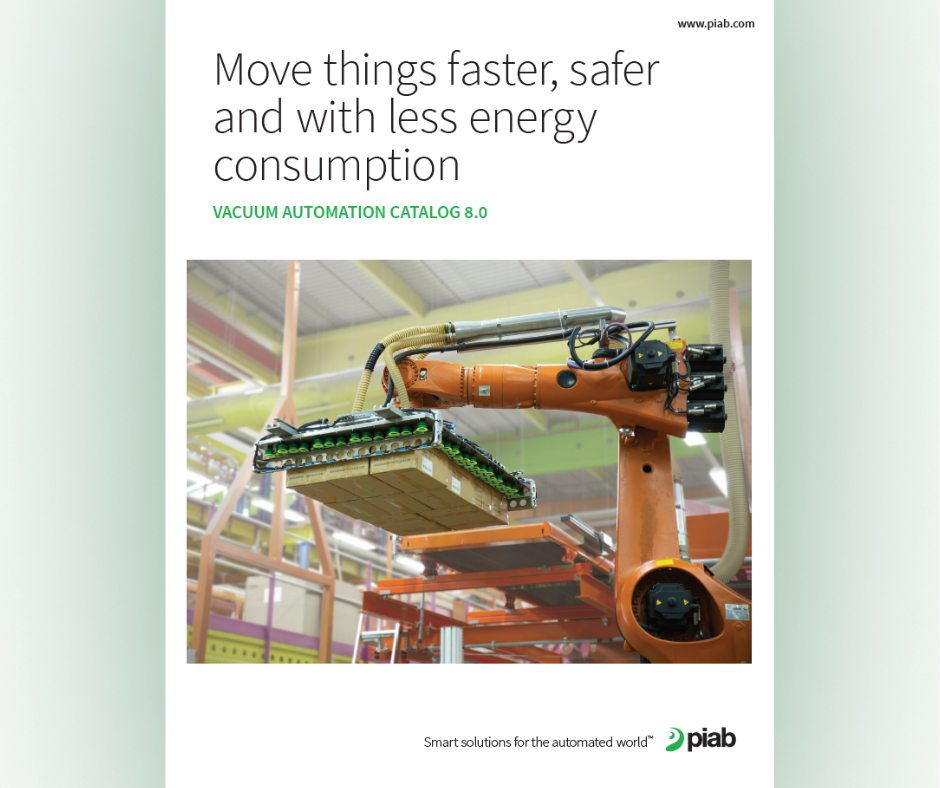

Piab offers an extensive range for all types of palletizing and de-palletizing operations, whether you're looking for ergonomic handling equipment, components and options to build your own gripper hand or ready-to-use palletizing gripper hand for industrial or collaborative robots. Piab also supplies demoulding and debottlenecking applications in the plastics industry with their range of modular components, parts and custom-made components from well-known brands when building your gripper hand. Advanced gripper solutions are complete gripper systems for specific fields of application. Ready-to-use grippers are designed to be mounted directly on the robot arm or toolholder. Several ISO-9409-1-compliant mounting interface options are available, facilitating installation on most robot models. Piab's advanced gripper solutions will simplify and even eliminate design times, facilitate installation and ensure that the latest components are used and sized correctly to achieve maximum performance and productivity for the user.

Gripping solutions for robots and cobots

Piab offers a wide range of products for all types of palletizing and de-palletizing operations, whether you're looking for ergonomic handling equipment, components and subsystems to build your own gripper hand, or ready-to-use palletizing gripper hands for industrial or collaborative robots. We also supply demolding and debottlenecking applications in the plastics industry with our range of modular components, parts and custom components from well-known brands when building your grippers. Advanced gripper solutions are complete gripper systems for specific fields of application. Ready-to-use grippers are designed to be mounted directly on the robot arm or toolholder. Several ISO-9409-1-compliant mounting interface options are available, facilitating installation on most robot models. Piab's advanced gripper solutions will simplify and even eliminate design times, facilitate installation and ensure that the latest components are used and sized correctly to achieve maximum performance and productivity for the user.

Accessories for systems and solutions

Piab's range of monitoring and control units for vacuum systems is unsurpassed when it comes to reliability. They focus on the total solution, right down to the smallest detail. Piab is fully aware that high-quality components are just as important as the design of vacuum pumps and suction pads, which are in a class of their own. Here you'll find everything you need to monitor and control vacuum systems. The common denominators are reliability, economy and control/monitoring accuracy.

Piab complete catalog

Suction cup catalog (en)

Kenos catalog

Robotic gripping solutions catalog

Ready to automate your tasks with Piab products?

Think you have an interesting project?

Piab products video

Piab business sectors

Piab specializes in automated process components and solutions to enable gripping, lifting and moving applications for our customers in all industries.

Food industry

The food industry is focused on hygienic and safe production that meets the stringent requirements of the FDA, EU, ATEX and other requirements without compromising on health, safety and product quality. Piab's innovative products and solutions are modular in design, ensuring the highest quality of finished products.

Instant food

In the production of instant foods, such as soups, noodles, dry sauces, etc., materials are often dusty and can be greasy. It is therefore essential to use equipment that is easy to clean and allows rapid changeover between products. For some material mixtures, dense-phase conveying will help reduce segregation. Piab's pneumatic conveyors are designed as a hermetically sealed system that willincrease productivity and guarantee employee health and safety.

What Piab has to offer

- Cost-efficiency: reduced waste thanks to smooth pneumatic conveying adjustment

- Innovative design: made from food-grade materials that meet industry requirements

- Hygiene and health: easy to clean and maintain

Applications

-

- Feeding to and from mixing units

- Product recovery

- Powder filling and packaging

Pet food

It's important to transport large quantities of feed quickly and efficiently without loss of product, while meeting industry standards. Pneumatic conveyors increase productivity and save space when transporting feed.

What Piab has to offer

- Cost-efficiency: reduced waste thanks to gentle pneumatic conveying

- Hygiene and health: easy to clean and maintain

- Small footprint: pneumatic conveyors won't compromise on limited space

Applications

-

- Feeding to and from mixing units

- Feed to and from the extruder

- Wrapping and packaging machine infeed

- Recovery

Café

Handling operations in the coffee industry is a tricky business, and the sector covers everything from large-scale industrial roasters to small-scale micro roasters, but all with the same goal: to deliver a high-quality product to end consumers, where coffee is taken care of at every level of the process. Piab's pneumatic conveyors are adaptable to your operations; for example, if you want to run your process with nitrogen instead of atmosphere, we can accommodate that. Most importantly, pneumatic conveyors won't change the characteristics of your product.

What Piab has to offer

- Hermetically sealed transport: preserves the freshness of oxygen-sensitive beans, without changing any of the coffee's characteristics

- Cost-efficiency: reduced waste thanks to smooth pneumatic conveying adjustment

- People-oriented: easy maintenance, hygienic and safe for human handling

Applications

-

- Supply of roasted coffee beans to and from grinding and crushing plants

- Feeding green coffee beans to roasting plants

- Coffee packing and packaging

- Recovery of coffee beans or powder

Sweets and candies

Typical materials transported by pneumatic conveyors in the confectionery and candy market are sugar in various forms, cocoa powder, flour and finished confectionery products. As materials change frequently, it is important to have conveying equipment that is versatile, easy to clean and allows for rapid changeover. Piab's SMART technology can automatically change parameters to better optimize your conveying equipment and production. Piab also offers food-grade suction cups and grippers for picking up finished products.

What Piab has to offer

- Cost-efficiency : reduced waste thanks to smooth pneumatic conveying adjustment

- Optimized production : customized pneumatic conveyors for confectionery and sweets

- Human-oriented: easy, hygienic and safe maintenance for human handling

Applications

-

- Direct contact with food

- Material feed to and from the screening unit

- Feeding to and from mixing units

- Feeding to and from the tablet press

- Powder recovery

- Feeding the packaging line with fine products

Bakery products

Typical materials conveyed by Piab's pneumatic conveyors in the bakery products market are various forms of flour, sugars, starches, seasonings, nuts, and so on. As materials change frequently, it's important to have conveying equipment that's versatile, easy to clean and allows rapid changeover. Piab also offers food-grade suction cups and grippers for picking up finished products.

What Piab has to offer

- Food-safe: hygienic and safe for direct food contact, easy to maintain and clean

- Easy to use : pneumatic conveyors are easily adjusted for fast material changeover

- Human safety: their hermetic system helps reduce exposure to dust

Applications

-

- Feeding to and from mixing units

- Feeding seasoning and sprinkling units

- Power supply for packaging machines

- Product recovery

- Direct contact with food

Nutraceuticals

For many nutraceutical products, the demands are as high as in the pharmaceutical industry, with similar challenges, such as cross-contamination and dust generation. Piab's pneumatic conveyors are designed to meet these challenges. As materials change frequently, it is important to have conveying equipment that is versatile, easy to clean and allows rapid changeover. Piab also offers food-grade suction cups and grippers for picking up finished products.

What Piab has to offer

- Small footprint: our pneumatic conveyors won't compromise on limited space

- Cost-efficiency : reduced waste thanks to smooth pneumatic conveying adjustment

- Hygiene and health: easy to clean and built to meet industry requirements

Applications

-

- Direct sales of nutraceuticals

- Sampling fiber drums and barrels

- Material feed to and from the mixer

- Material feed to and from crushing and grinding plants

- Material feed to and from the screening unit

- Transport to/from metal detection equipment

- Feeding to and from capsule filling

- Feeding to and from the tablet coating machine

- Feeding to and from the tablet press

- Powder recovery

- Powder packaging and conditioning

Snacks

In the production of snacks, it is essential to use equipment that is easy to clean and allows rapid changeover between products. Pneumatic conveyors are used to transport aromatics to the seasoning machine, or to retrieve broken products from the wrapping/packaging stage and return them to the previous stage. Manual feeding of snacks can easily be replaced by a pneumatic conveyor, since powder can be picked up from a drum or container.

What Piab has to offer

- Innovative design: made from food-grade materials that meet industry requirements

- Efficient: complete and fast for transporting products from point A to point B

- Hygiene and health: easy to clean and maintain

Logistics and warehousing

Piab manufactures highly efficient products covering all aspects of materials handling in processing and distribution centers. Piab's automated solutionsoptimize pick-to-location, parcel and package handling, palletizing and de-palletizing.

E-commerce and automated warehouses

In fast-moving e-commerce, automatic shuttles or automatic guided vehicles bring products to the order-taking station, where items are placed in standard crates/boxes, or kept in their original packaging. Piab offers vacuum grippers, vacuum systems and customized components to help increase the efficiency of your automation within your operations.

What Piab has to offer

- Reliability: innovative grippers with exceptional grip on thousands of product and part combinations

- Optimized operations: all solutions are designed to increase automation and improve energy efficiency

- Speed: with Piab's palletizing solutions, we enable you to improve the speed of your operations thanks to reactive gripping technology.

Applications

-

- Order picking / bin picking / random bin picking

Palletizing and de-palletizing

Just about everything shipped in the world ends up on a pallet at one time or another. Piab offers a wide variety of products to meet your palletizing and de-palletizing needs, whether you're placing an item on a pallet or removing it. All tools are designed to ensure that your operations are highly efficient, low-maintenance, safe and that no product or human is harmed in the process.

What Piab has to offer

- Reliability: our gripping hands are designed to ensure safe operation of pallet after pallet.

- Speed: with Piab's palletizing solutions, we enable you to improve the speed of your operations thanks to reactive gripping technology.

- Improved uptime: maintenance is simple and reduced to a minimum, saving you time

Applications

-

- Pallet handling and positioning

- Sheet feeder

- Open-top trays and containers

- Boxes and containers

- Bags, pouches and packages

Intralogistics

At the right time, in the right place. This is a key motto when ensuring that your materials, components and parts are ready for the next step in the process. All your intralogistics can be fully automated with vacuum automation, conveying systems, automated guided vehicle solutions, kitting robots, pick and place stations and sorting stations. Piab offers a wide variety of solutions to enable vacuum automation within intralogistics.

What Piab has to offer

- Innovation: using the best components, ergonomic lifting systems and gripping hands, we can help you optimize any production line.

- Reliability: Piab's solutions will ensure that the right products are in the right place in your plant.

- Customization: our wide range of modular components can be adapted to meet the needs of your operations

Applications

-

- Order picking / bin picking / random bin picking

- Robotic picking, placement and packaging

- CMS roll handling

- Kitting

Packaging and wrapping

Piab has a long history of setting standards for the packaging industry. Over the years, Piab has developed a wide range of high-quality components and solutions to helpincrease process performance and ensure minimum downtime. Packaging plays a key role in almost every industry in the world, and Piab's heritage has created the best solutions for fast, safe and efficient handling of individual and packaged products.

Palletizing and de-palletizing

Just about everything shipped in the world ends up on a pallet at one time or another. Piab offers a wide variety of products to meet your palletizing and de-palletizing needs, whether you're placing an item on a pallet or removing it. All tools are designed to ensure that your operations are highly efficient, low-maintenance, safe and that no product or human is harmed in the process.

What Piab has to offer

- Reliability: our gripping hands are designed to ensure safe operation of pallet after pallet.

- Speed: with Piab's palletizing solutions, we enable you to improve the speed of your operations thanks to reactive gripping technology.

- Improved uptime: maintenance is simple and reduced to a minimum, saving you time

Applications

-

- Pallet handling and positioning

- Sheet feeder

- Open-top trays and containers

- Boxes and containers

- Bags and packages

Cartons and trays, forming and shaping

Piab takes increased speeds and cycles into account when developing products to improve the efficiency of your packaging line. Multiple aspects, such as carton material, forming processes, cycle speed, energy savings and intelligent monitoring are all considered to help ensure maximum reliability with no missed catches.

What Piab has to offer

- Reliability: suction pads are available in a wide variety of designs and materials to provide a reliable seal on seized equipment.

- Enhanced performance: products designed for high-speed automation and low energy consumption

- Intelligent technology: vacuum monitoring based on your operating specifications

Applications

-

- Tray forming, unloading and loading

- Rotary carton feeder

- Case/carton forming, case/carton opening and closing

Pick, place and pack boxes, trays and crates

Piab's suction cups and vacuum systems are specially designed to meet the diverse needs of the packaging industry at no cost to performance or reliability. Our food-grade suction cups are designed for direct food contact. If you're looking to handle liquid-filled bags, we've got the world's best bag vacuum for you. Vacuum solutions offer an optimal and responsive way to pick and place objects.

What Piab has to offer

- Reliability: suction pads are available in a wide variety of designs and materials to provide a reliable seal on seized equipment.

- Enhanced performance: products designed for high-speed automation and low energy consumption

- Intelligent technology: vacuum monitoring based on your operating specifications

Applications

-

- Direct food contact

- Robotic picking, placement and packaging

Handling of bags, pouches and flexible packaging

Flexible packaging materials are the generic term for flexible packaging made from film, foil or paper. Common shapes include pouches, bags, sachets and flat-bottom envelopes. These packages are often formed, filled and sealed in a vertical or horizontal form-fill-seal machine. Innovative vacuum systems enable you to fill and seal the bag, as well as handle the bag without damaging the product.

What Piab has to offer

- Piab has the world's best flexible packaging bags, pouches and cups on the market!

- Reliability: suction pads are available in a wide variety of designs and materials to provide a reliable seal on seized equipment.

- Intelligent technology that monitors vacuum according to the specifications of your operations

Applications

-

- Bag and pouch handling

- Opening bags and pockets

- Powder filling and packaging

Pharmaceutical products

The pharmaceutical industry requires the safest, most hygienic and highest quality equipment to meet industry requirements and regulations. Piab products exceed these requirements, optimizing productivity at no cost to human safety.

Powder

In the production of pharmaceutical products, powder is transported through the process stages either by manual handling or an automated solution. The challenges are many, and include employee health and safety, contamination, material segregation, product disposal, compliance and quality. Piab's solutions are tailored to your needs, ensuring a hermetically sealed and safe system between stages of your process. Piab offers intelligently designed solutions that effectively connect flow from start to finish.

What Piab has to offer

- Health and safety: Piab builds pneumatic conveyors for dust-free production

- Efficiency: pneumatic conveyors are designed to transfer powders rapidly without segregating the material.

- A step ahead: Piab exceeds industry standards without compromising safety

Applications

-

- Capsule filling

- Material feed to and from the screening unit

- Material feed to and from crushing and grinding plants

- Material feed to and from the mixer

- Material feed to and from the fluidized-bed dryer

- Reactor filling

- Conveying powder to and from the drum or fiber drum

- Powder recovery

- Powder packaging and conditioning

Tablets and capsules

In the production of pharmaceutical products, tablets and capsules are transported through the process stages either by manual handling or by an automated solution. The challenges are many, and include employee health and safety, contamination, material segregation, product disposal, compliance and quality. Piab's solutions are tailored to your needs, ensuring a hermetically sealed and safe system between stages of your process. Piab offers intelligently designed solutions that effectively connect flow from start to finish.

What Piab has to offer

- Cost-efficiency: reduced waste thanks to smooth pneumatic conveying adjustment

- Efficiency : pneumatic conveyors are designed to transfer powders rapidly without segregating the material.

- People-oriented: easy maintenance, hygienic and safe for human handling

Applications

-

- Feeding to and from the tablet or pill press

- Feeding to and from the tablet coating machine

- Feeding to and from capsule filling

- Power supply for packaging machines

- Transport to/from metal detection equipment

- Recovery of materials, tablets and capsules

Plastics

Increase productivity and efficiency with innovative Piab products and solutions for the plastics industry. Remove ready plastic parts from the mold while guaranteeing quality and optimum production rates.

Injection molding

A very common production process in plastic part manufacturing is injection molding, producing high quality requirements that demand reliability and performance in terms of handling during part demolding/removal, as well as during stripping and cutting operations. A secure grip with mechanical and vacuum gripping is essential to avoid damage to parts. To enable high-productivity part combination, removal and debottlenecking can be performed with the same gripping hand.

What Piab has to offer

- Quality : gripping hands that demould your automotive parts safely, cycle after cycle.

- Improved production: innovative component systems to manage simple and complex cuts

- Reliability : robust design of components and gripper hand systems

Applications

-

- Stripping / cutting

- Removing plastic parts

Additive manufacturing

Additive manufacturing is a fast-growing sector, with a strong emphasis on technology to continue improving productivity and efficiency, while maintaining high standards of quality, health and safety. The raw materials used are mainly polymers and metals, each with individual requirements.

Metal additive manufacturing

Safety and health are major concerns when transporting metal powders from one process step to another. Piab's pneumatic conveyors help move metal powders quickly and safely, without external contamination or exposure to hazardous materials, and at no cost to production efficiency.

What Piab has to offer

- Productivity and efficiency : automating powder handling and transport

- Employee health: conveyors move metal powders without compromising safety

- Customized solutions: solutions tailored to your needs

Applications

-

- Filling the printer with metal powder

- Filling the sieve or hopper with metal powder

- Recovering metal powder in the printer

Automotive

Piab helps the automotive industry increase productivity and save energy with innovative, reliable products at no cost to human safety. From start to finish, Piab is present at every level of the production line, from the press shop, to the chassis, to final assembly, and even component production.

Press shop

Slippery panels due to oil, narrow pick-up zones, reliability and speed in the press are all factors to consider when designing a vacuum system of suction cups and vacuum ejectors. Using our products created specifically for the automotive industry, sheet metal from the press shop is moved onto the press quickly and efficiently.

What Piab has to offer

- Tailor-made suction cups: unique design for handling oily plates; our suction cups are made to hold their grip.

- Efficiency: Piab vacuum cups and ejectors are designed to match stamping line speeds

- Reliability: safe and robust for moving heavy parts at no cost to human safety

Applications

-

- De-stacking metal plates

- Press-to-press transfer of metal plates

- End-of-line shelving for metal panels

Body assembly

In the automotive industry, body assembly speed and safety are top priorities. Metal plates are heavy and oily, requiring the use of our energy-efficient vacuum gripping solutions and specially designed friction pads to help lift, hold and move products along the assembly line. Piab solutions are flexible during production, robust and reliable, offering maximum safety in the event of a power cut.

What Piab has to offer

- Tailor-made suction cups: unique design for handling oily plates; our suction cups are made to hold their grip.

- Efficiency: Piab vacuum cups and ejectors are designed to match stamping line speeds

- Reliability: safe and robust for moving heavy parts at no cost to human safety

Applications

-

- Underbody, engine and trunk assembly

- Assembling bodywork and frames

- Closures - Deburring stations - Interior and exterior assembly

- Self-steering unloading and assembly

- Parts selection

Final assembly

In final assembly (after the paint shop), the vehicle is fitted with heavy exterior and interior parts, such as bumpers, dashboards, tires, windscreens, and even brakes and air conditioning systems. Piab vacuum and robot products help to lift these parts safely and efficiently. And with a wide choice of suction cups, you'll find the right grip without leaving any marks.

What Piab has to offer

- Non-branded parts: our large selection of suction cups guarantees brand-free handling

- Efficiency: suction cups and vacuum ejectors are designed to optimize assembly line speed

- Reliability: vacuum systems and innovative components ensure safe handling of delicate, heavy and high-value parts at no cost to human safety.

Applications

-

- Ergonomic on/off tools for doors

- Glass assembly and installation

- Fuel tank assembly and installation

- Assembly of exterior and interior finishing components

- Parts selection

Plastic molding workshops

Cars are made up of a large number of plastic parts which require reliable handling during demolding and part handling, as well as during stripping and cutting operations. A secure grip with mechanical and vacuum gripping is essential to produce high-quality, damage-free plastic parts.

What Piab has to offer

- Quality: gripper hands that safely handle your automotive parts cycle after cycle

- Improved production: innovative component systems to manage simple and complex cuts

- Reliability: robust design of components and gripper hand systems

Applications

-

- Stripping plastic parts

- Removing plastic parts

Welded body components

Before the car panels are stamped in the stamping shop, the large metal plate elements are welded together to optimize safety and vehicle structure. Piab helps to load and unload these heavy metal plates thanks to their innovative suction gripper technology. Their suction cups guarantee transport of the metal plates without creating deformation, and deposit the plates safely, resulting in faster cycle times and higher productivity.

What Piab has to offer

- No deformation: their suction cups are designed to carry and deposit heavy plates without creating deformation.

- Improved productivity: vacuum systems and suction cups guarantee faster cycle times

- Reliability: vacuum systems and innovative components ensure safe handling of delicate, heavy and high-value parts at no cost to human safety.

Applications

-

- Loading and unloading metal plates

Ready to automate your tasks with Piab products?

Think you have an interesting project?

The Company Piab

Piab's founder, Sven Tell, developed a uniquely designed compass inspired by his passion for the mathematical formula "pi", which also inspired the company's name. Since its foundation in 1951, Piab has continued to innovate, developing products such as vacuum ejectors, vacuum pumps and pneumatic conveyors. The company has registered over 65 patents and continues to provide its customers with progressive gripping, lifting and moving solutions. Piab was sold in 2006 and is now wholly owned by Patricia Industries, part of Investor AB, but family spirit and innovation remain at the heart of the company.

Piab specializes in automated process components and solutions to provide gripping, lifting and moving applications for customers in all industries, with a particular focus on packaging, food, pharmaceuticals, chemicals, logistics and warehousing, plastics and automotive.

Ready to automate your tasks with Piab products?

Think you have an interesting project?

Address

100 Goyer Street, room 103

La Prairie (QC)

J5R 5G5

Phone

514.745.1987

1.800.361.1684

info@pneumac.qc.ca