Are you in the process of automating processes in your company?

Equipment purchasing decisions are fraught with pitfalls, especially when the outcome directly impacts production capacity, return on investment (ROI) and workplace safety.

When specifications look the same and it seems like it's all about capital investment, the reputation and track record of equipment manufacturers can be a game changer.

Here's everything you need to know about the company and Universal Robots' products

Sections

UR Robot Products

UR Robot Specifications

What is a Collaborative Robot?

The UR+ Ecosystem

Processes to Automate with Universal Robots

How much does a UR Robot cost?

The Universal Robots Company

Your Next Step with Universal Robots

The Products UR Robots

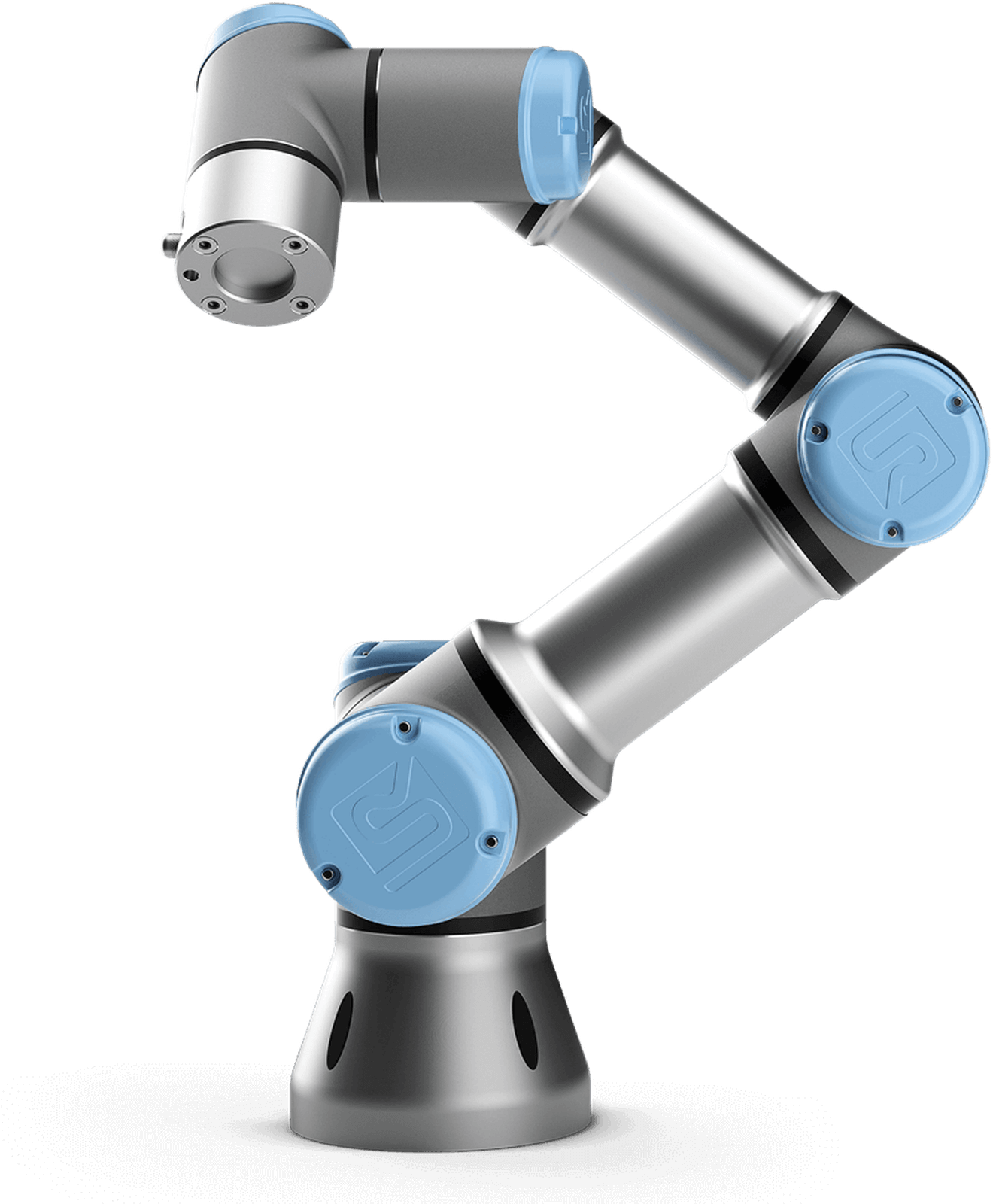

Universal Robots has designed several similar-looking robots, each differing in range, payload and size.

With a wrist-mounted force and torque sensor, numerous safety features, and increased accuracy and sensitivity, these new robots now enable users to automate a wide range of processes with confidence.

- Their first robot, the UR5, was launched in 2008 and revolutionized the world of robotics by integrating the collaborative aspect into production cells.

- The UR10 (10 kg payload) was developed in 2012 to meet a growing demand for handling heavy parts and objects.

- And finally, in 2015, the company released the UR3 to provide a low-cost solution, and facilitate automation of short-range, low-payload tasks.

- Subsequently, in 2018,Universal Robots upgraded its robots by rolling out the e-Series (UR3e, UR5e and UR10e).

The UR e-Series robots also offer a redesigned teach pendant to make it more intuitive and a programming interface with more wizards.

With features that comply with ISO 13849-1, category 3, performance level "d", and ISO 10218-1, the new technologies implemented by Universal Robots greatly facilitate effective collaboration between humans and machines in a production environment.

Depending on a risk analysis, the robotic cell may not require safety fences and allow your employees to work in conjunction with the robot, thus reducing the floor space required and the complexity of the project.

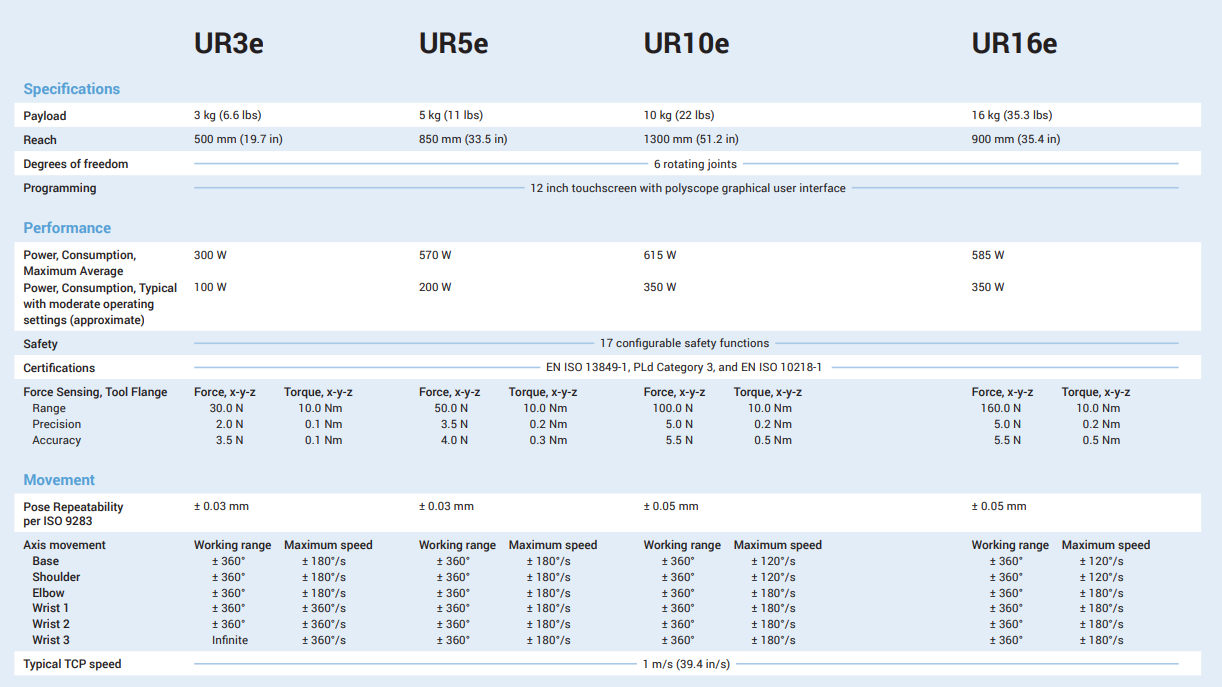

UR Robot Specifications

What is a collaborative robot?

collaborative + robot = cobot

Among other things, cobots are characterized by their low investment that pays off, their small footprint that requires virtually no redesign of the production floor, their versatility and adaptability, and their many customizable safety features.

Reasons for manufacturers to acquire one or more collaborative robots include labor shortages, the need to cover night shifts, safety issues, accuracy and repeatability, process quality and results.

One of the goals of integrating collaborative robots is to reassign people who do monotonous and repetitive work to high value-added tasks.

Low Cost

Profitability

Cellular Approach

Simplicity and Security

Ready to automate your tasks with a Universal Robots collaborative robot?

Think you have an interesting project?

The ecosystem UR+

At Pneumac Automationwe have extensive knowledge of and confidence in Universal Robots (UR) products.

Thanks to UR, robot programming is no longer reserved for computer coding experts.

These are the most widely used collaborative robots in the world, and for good reason! UR makes the UR+ ecosystem available to all, a pool of robot components and end effectors, supplied by third party companies.

Looking for a vision system? An adaptive hand? A palletizing solution?

UR+ is probably the most reliable directory to get you kits that meet your exact needs.

UR puts each manufacturer through a rigorous process of testing, documentation validation, quality control, and certification of safety features before including them in the UR+ ecosystem.

Our UR Plus Recommendations

Processes to Automate with Universal Robots

At Pneumac Automationwe have extensive knowledge of and confidence in Universal Robots (UR) products.

Thanks to UR, robot programming is no longer reserved for computer coding experts.

Transfer of objects (pick and place)

Picking up parts or objects at the point of entry into a cell (conveyor, chute, bin, manual feed) and depositing them at another location, either to finish (packing) or to continue the production process (next cell).

Power supply for machines

UR robots can somewhat replicate the often repetitive work of a person feeding a CNC machine - opening and closing doors, triggering part processing, sending and receiving signals to start or stop production, moving parts to be processed. These include lathes, milling machines, presses and drills.

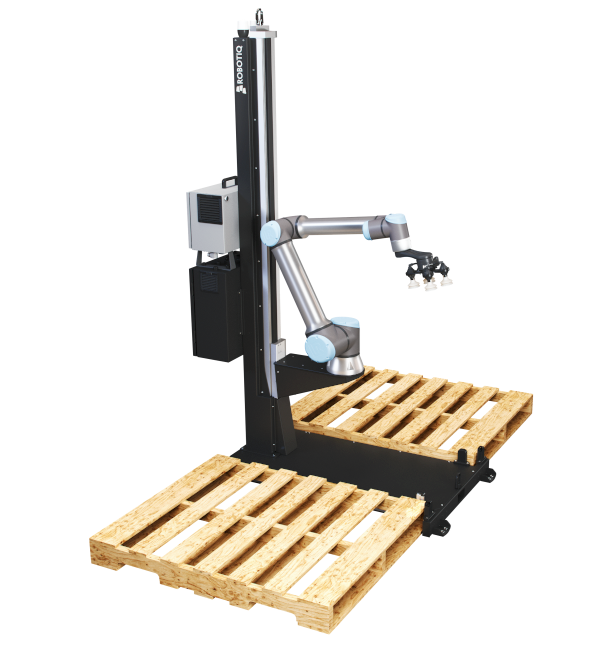

Palletizing

With the latest additions to the UR range (UR16e, UR20 - not to mention the UR10e), Universal Robots has carved out a niche in the packaging and palletizing industry. In addition, palletizing solution manufacturers and integrators are taking advantage of Universal Robots' intuitive software to create very user-friendly programming interfaces. Cobots can now compete with industrial robots to automate these tasks.

Assembly

This includes screwing, mounting, fastening, connecting and other handling tasks of parts and subassemblies. With their force and torque control features, UR robots are ideal for these small, repetitive jobs.

Finishing, polishing, sanding and deburring

Tasks that require contact between the effector tool and the surface to be treated, and continuous movement of the robot. UR robots can easily reproduce all kinds of fluid motions accurately and repeatably by means of force control.

Welding

UR robots are ideal for this type of work, which traditionally requires the incorporation of numerous safety measures to avoid material collisions and potential injuries.

Inspection and quality control

With high repeatability, unparalleled accuracy, resolution down to a few microns (depending on the specifications of the end-user) or integrated vision systems, Universal Robots cobots can automate inspection and quality control tasks in all kinds of environments.

How much does a UR Robot cost?

Generally speaking, a collaborative robot represents an investment in the range of $40,000 to $70,000, but this is a price range to be taken with a grain of salt.

150,000 to $250,000

the price of the entire cell

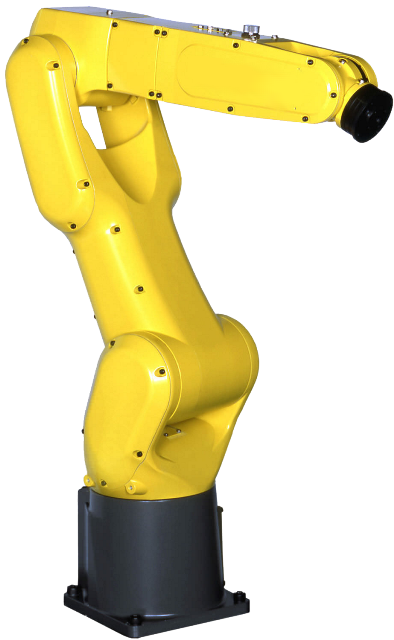

In comparison, the integration of industrial robots costs about 10 times more.

40,000 to $70,000

the acquisition of a collaborative robot

The most important point for the buyer is to distinguish between the price of the cobot and the price of the entire robot cell. Depending on the complexity of the project, the retrofit required, the resources deployed in integration and the process to be automated, the total cost can vary between $150,000 and $250,000.

10 TIMES MORE EXPENSIVE

the integration of industrial robots

The Company Universal Robots

Universal Robots A/S is a high-tech company based in Odense, Denmark. It became part of the American company Teradyne in 2015. Founded in 2005, UR has bet big from the start on thecollaborative aspect of robotics. Although the safety aspect is at the forefront of the development of its robots, the company distinguishes itself by a schematic programming through a very user-friendly very user-friendly and intuitive interface.

At the dawn of the fourth industrial revolution (Industry 4.0), UR quickly established itself as a leader in collaborative robotics. Where most industries had turned to rigid and expensive industrial robotics, VSEs and SMEs saw the hope of automating their processes with light, safe and adaptive solutions.

And that's exactly where Universal Robots comes into its own.

Your Next Step with Universal Robots

In short, Universal Robots is a company, a brand and an ecosystem that provides users - novices and experts alike - with all the tools to begin the journey to automation in an affordable, cost-effective, safe and intuitive way.

You probably have other questions specific to your industry or business. That's why we've provided a guide that serves as a checklist, a checklist and a decision support tool.

In addition, we offer you another summary tool that neatly summarizes the benefits of Universal Robots collaborative robots and the main reasons to transform your business with cobots.

Otherwise, we remain at your disposal to discuss your automation project. There is nothing like a human to talk about robots!

Address

100 Goyer Street, room 103

La Prairie (QC)

J5R 5G5

Phone

514.745.1987

1.800.361.1684

info@pneumac.qc.ca