Our products Robotiq

Manufacturers are reluctant to use robots in their factories because of their complexity and cost.

Robotiq's products and know-how simplify the implementation of collaborative robots, so that factories can start production without wasting time. Robotiq works with a global network of interconnected robotics experts who support manufacturers around the world.

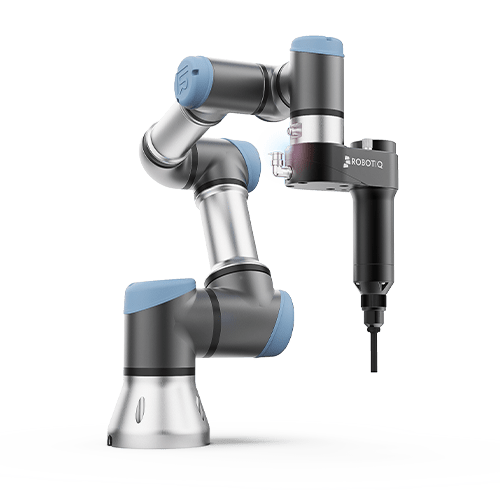

2-finger hands 2F-85 and 2F-140

The 2F-85 and 2F-140 adaptive hands are the hands for collaborative robots. Take advantage of them to perform a full range of applications with reduced production lead times: no robotics expertise is required. Your robot cell will be far more flexible and reliable thanks to these adaptive hands.

Features

● Patented finger design enables internal and external parallel gripping, as well as a unique all-encompassing gripping mode

● Automatic part detection and position display

Adaptive 3-finger hand

The 3-finger adaptive hand is ideal for advanced manufacturing and robotics research. It adapts to the shape of the object and guarantees a firm grip, so you can concentrate on the task and not the grip.

Features

Adaptive Hand-E

Hand-E's remarkable precision and 50 mm parallel stroke are ideally suited to assembly tasks requiring high accuracy. Its sealed design makes it reliable under the toughest manufacturing conditions, including CNC machining. Hand-E's design meets the requirements of ISO/TS 15066 (maximum force, rounded edges, self-locking functions and more), making it the gripper for collaborative robots.

Features

- Hand model with 50 mm stroke, ideal for collaborative robots

- Seamless integration with Robotiq's FT 300 wrist camera and force sensor

- Ergonomic shape for hand guidance

- Intuitive interface for rapid deployment and use

- No training required

- Automatic part detection, positioning reaction and part validation

- Precision and durability

- High strength and payload

- Withstands harsh manufacturing conditions

Vacuum grippers

Robotiq vacuum grippers can perform a wide range of tasks, and are ideally suited to handling objects of various compositions: regular and irregular surfaces, cardboard, glass, (dry) sheet metal, plastic and more. Thanks to the customizable mounting bracket and unique junction fittings, Robotiq gives manufacturers full control over their vacuum gripper, so that it meets their exact requirements.

Features

- Connected to the robot's wrist

- Operates without compressed air

- Easy to handle

- Powerful flow

- Compact design for collaborative robots

- Low noise

- Simple programming

- Quick installation

- No training required

- Natural compatibility with Robotiq's FT 300 wrist camera and effort sensor

- Industrial-quality components

- Low maintenance

- Capacity corresponding to maximum robot payload

Finishing Copilot

Easy to integrate, easy to use

You don't need extensive knowledge of robotics to use Finishing Copilot. Its intuitive programming interface guides you towards the efficient completion of a finishing task.

Features

- Set up an external end-effector point

- Apply a contact offset

- Generate finishing paths with fewer than 10 waypoints

- Achieve precision to within 0.2 mm (like Universal Robots)

- Look for surfaces

- Perform various types of insertions

- Control the robot with one hand

- Follow complex trajectories

- Modify trajectories point by point

- Apply a constant force and define the stiffness on each axis

- Reset sensor values

Force Copilot

Force Copilot is an intuitive software package for taking advantage of the force sensor integrated into e-Series robots. Program complex robotic movements in just a few minutes: no robotics expertise required! The result is a reliable, flexible robot cell.

Features

- ActiveDrive toolbar

- Trajectory node

- FT sensor to zero" node

- Insertion" node

- Search surface" node

- Force control node

- Force event" node

- Collision detection" node

- Multipoint trajectory node

FT 300-S load cell

Transform your production process with the most advanced force-control applications on the market. Program complex robotic movements in just a few minutes: no robotics expertise required! The result is a reliable, flexible robot cell.

Features

- IP65

- Designed to be compatible with Universal Robots CB series robots

- Includes intuitive Force Copilot programming interface

- Tool weight adjustable according to center of gravity

- Sensor value reset

- Manually guided robotic movement

- Precise object positioning

- Alignment

- Indexation

- Insertion

- Complex trajectories

- Constant strength and rigidity for each axis

- Takes precise, reproducible, high-resolution measurements

- Its rigid metal composition ensures high precision

Wrist camera

Robotiq's wrist camera is designed for industrial use with Universal Robots. Learn new parts and detect features quickly to ensure repeatable pick-up.

Features

- Compact, slim aluminium body with watertight hardware adapted to industrial needs.

- The camera fits perfectly on the wrist of Universal Robots.

- Programming software that runs directly on the programming interface.

- Three flexible multi-object learning methods.

- Precise teaching of a part from its CAD file.

- Automatic and manual adjustment of lighting, focus, exposure and more.

- Color validation system.

- Add traceability to your assembly line with barcode and 2D code reader functionality.

- Install a Robotiq tag on your equipment, trays or clamps to locate them with the "Visual offset" function.

- Multilingual software (ENG, FR, ES, DE, ZH, JP).

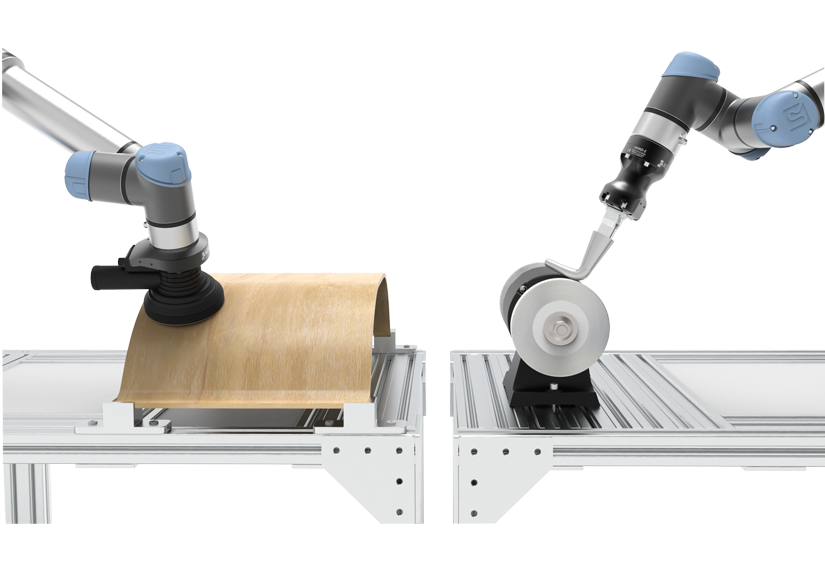

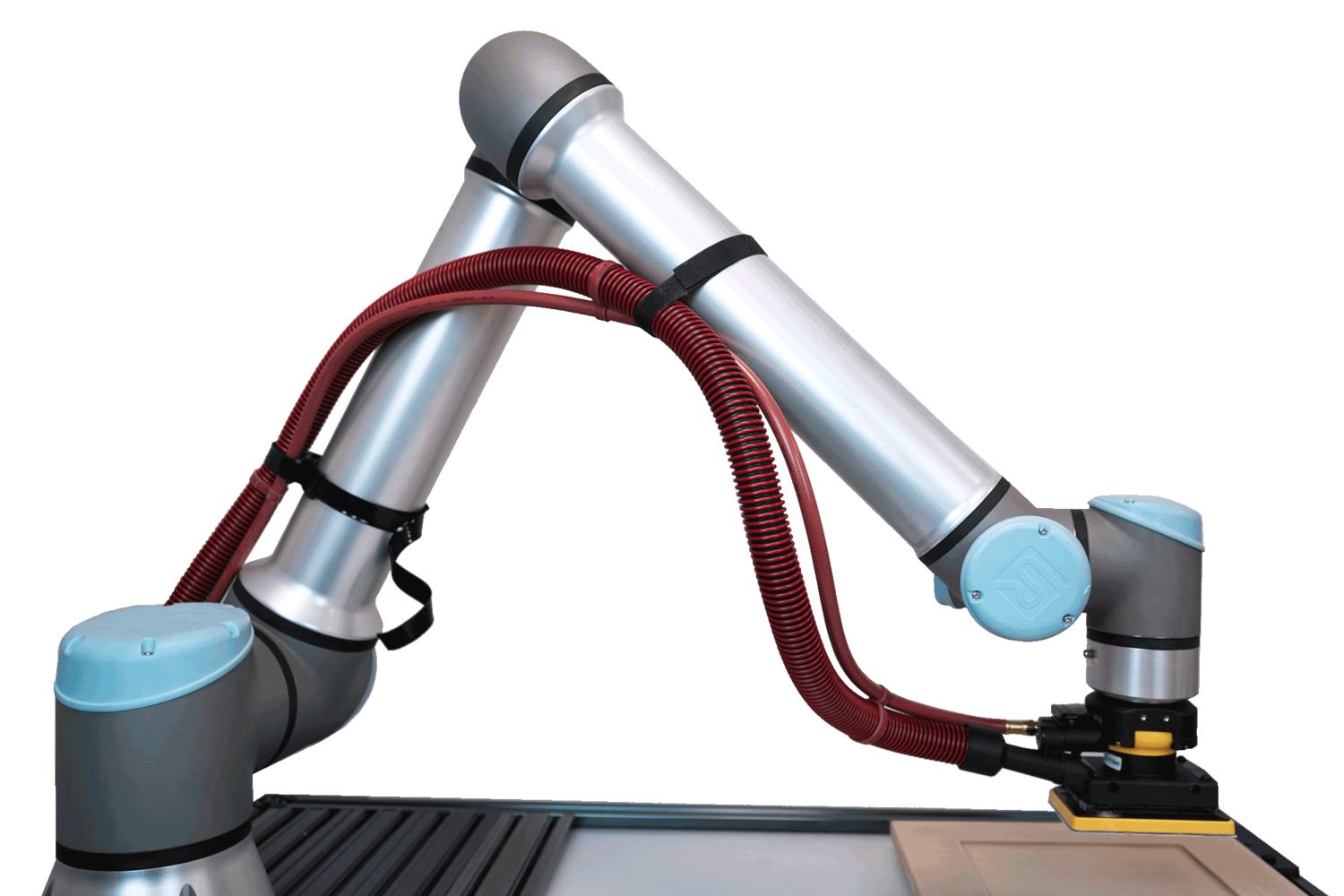

Sanding kit

Robotiq's sanding kit enables you to work on a wide range of surfaces.

Carbon fiber, fiberglass, metal, plastic, solid surface and wood

Features

5. Getting Started Guide

Surface finishing kit

Robotiq's Surface Finishing Kit is compatible with all Mirka and Dynabrade brand finishing tools, and automates finishing tasks on a wide variety of surfaces.

Carbon fiber, fiberglass, metal, plastic, solid surface and wood

Features

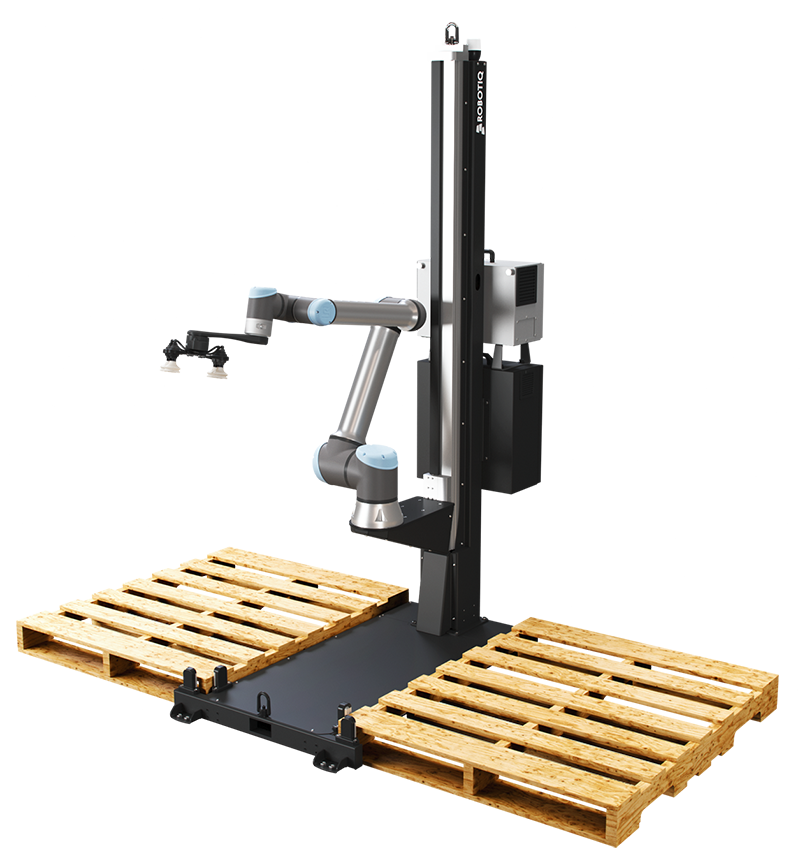

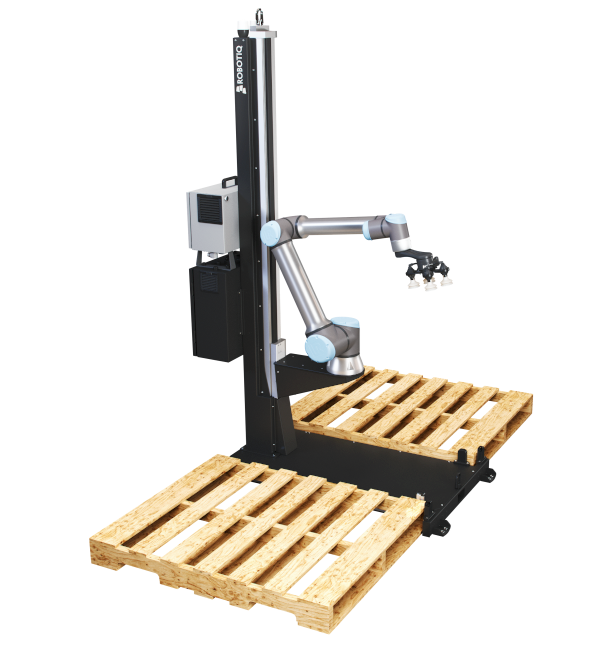

Palletizing solution

Elevate your workforce! Robotiq provides an integrated solution to the risk of labor shortages and injuries caused by tedious, repetitive palletizing tasks.

Features

Adaptability

Easily adapts to your production schedule. No need to stop your production line for hours.

Return on investment (ROI)

Deployment

Thanks to perfect compatibility between components, the solution takes up little space and adapts to your current layout.

No external PC required.

Security

Screwing solutions

Increase your workforce. Deploy a robotized screw cell in two weeks and free up employees for higher value-added tasks.

Features

Production changes in 5 minutes

Constant screwing in continuous operation

Intuitive deployment

More injuries and happier staff

Solution for CNC machine feeds

Peace of mind that your machines will always be running thanks to affordable automation.

Features

Ensuring constant production

Turn your back on complexity

Deployment in just a few hours on any CNC machine

Get a quick return on your investment

Ready to automate your tasks with Robotiq products?

Think you have an interesting project?

Some interesting about Robotiq products Robotiq free download.

Palletizing solution (en)

How to automate a screw cell

Loading and unloading machines: improving productivity with robotics (en)

The Company Robotiq

Robotiq is the people behind the robots: a team of enthusiasts grouped together in a worker-shareholder cooperative, working in concert with an international network of partners.

Manufacturers are reluctant to use robots in their factories because of their complexity and cost. The Robotiq tools and know-how simplify the implementation of collaborative robots so that factories can start production without losing time. Robotiq works with a global network of interconnected robotics experts who support manufacturers around the world.

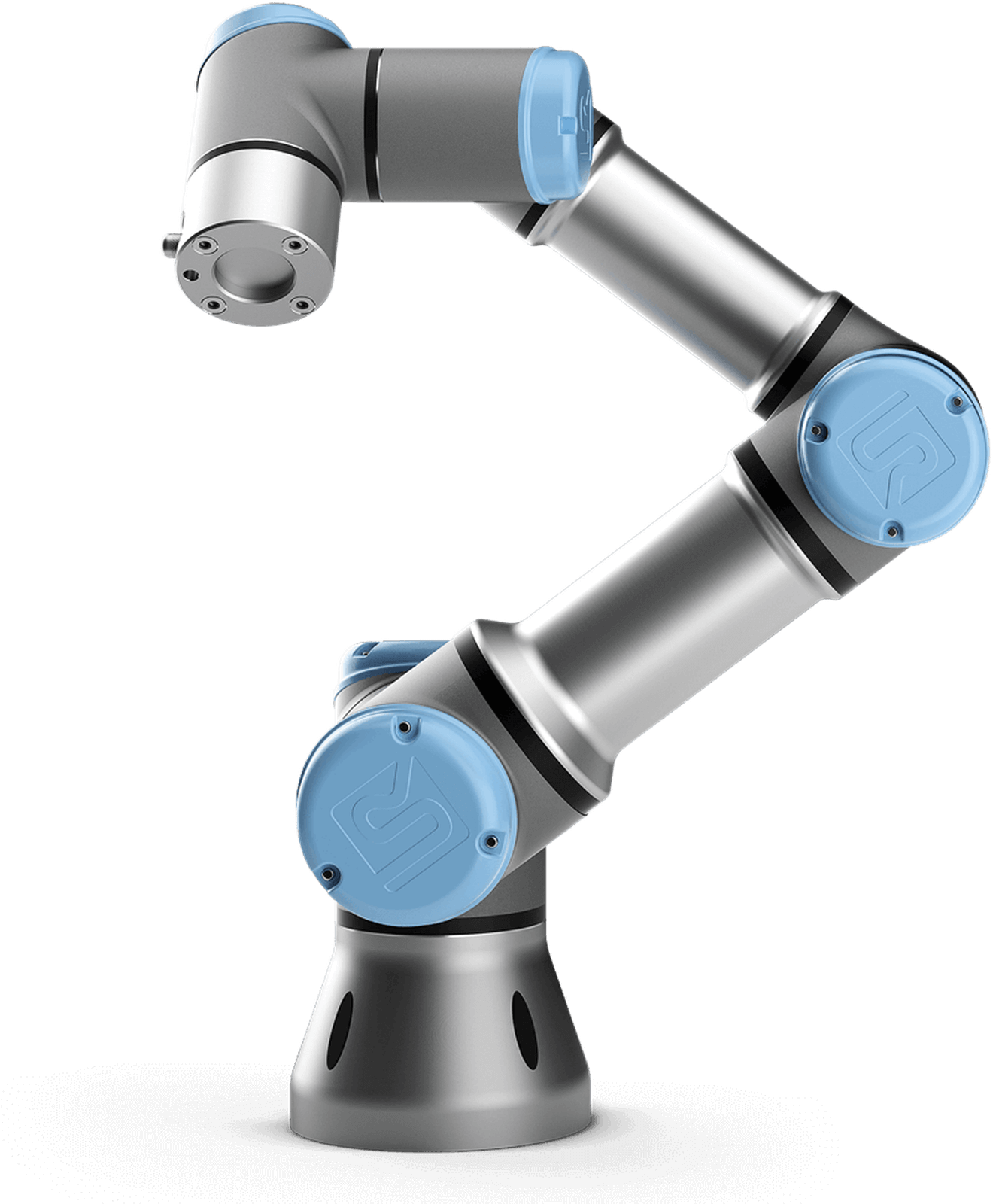

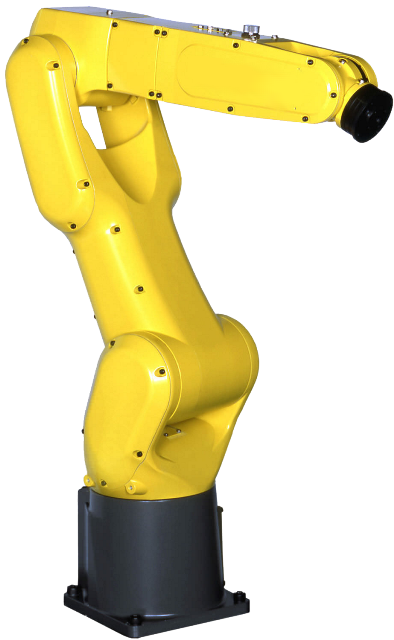

What is a collaborative robot?

collaborative + robot = cobot

Among other things, cobots are characterized by their low investment that pays off, their small footprint that requires virtually no redesign of the production floor, their versatility and adaptability, and their many customizable safety features.

Reasons for manufacturers to acquire one or more collaborative robots include labor shortages, the need to cover night shifts, safety issues, accuracy and repeatability, process quality and results.

One of the goals of integrating collaborative robots is to reassign people who do monotonous and repetitive work to high value-added tasks.

Low Cost

Profitability

Cellular Approach

Simplicity and Security

The ecosystem UR+

At Pneumac Automationwe have extensive knowledge of and confidence in Universal Robots (UR) products.

Thanks to UR, robot programming is no longer reserved for computer coding experts.

These are the most widely used collaborative robots in the world, and for good reason! UR makes the UR+ ecosystem available to all, a pool of robot components and end effectors, supplied by third party companies.

Looking for a vision system? An adaptive hand? A palletizing solution?

UR+ is probably the most reliable directory to get you kits that meet your exact needs.

UR puts each manufacturer through a rigorous process of testing, documentation validation, quality control, and certification of safety features before including them in the UR+ ecosystem.

Process Automation with Robotiq and Universal Robots

At Pneumac Automationwe have extensive knowledge of and confidence in Universal Robots (UR) products.

Thanks to UR, robot programming is no longer reserved for computer coding experts.

Transfer of objects (pick and place)

Picking up parts or objects at the point of entry into a cell (conveyor, chute, bin, manual feed) and depositing them at another location, either to finish (packing) or to continue the production process (next cell).

Power supply for machines

UR robots can somewhat replicate the often repetitive work of a person feeding a CNC machine - opening and closing doors, triggering part processing, sending and receiving signals to start or stop production, moving parts to be processed. These include lathes, milling machines, presses and drills.

Palletizing

With the latest additions to the UR range (UR16e, UR20 - not to mention the UR10e), Universal Robots has carved out a niche in the packaging and palletizing industry. In addition, palletizing solution manufacturers and integrators are taking advantage of Universal Robots' intuitive software to create very user-friendly programming interfaces. Cobots can now compete with industrial robots to automate these tasks.

Assembly

This includes screwing, mounting, fastening, connecting and other handling tasks of parts and subassemblies. With their force and torque control features, UR robots are ideal for these small, repetitive jobs.

Finishing, polishing, sanding and deburring

Tasks that require contact between the effector tool and the surface to be treated, and continuous movement of the robot. UR robots can easily reproduce all kinds of fluid motions accurately and repeatably by means of force control.

Welding

UR robots are ideal for this type of work, which traditionally requires the incorporation of numerous safety measures to avoid material collisions and potential injuries.

Inspection and quality control

With high repeatability, unparalleled accuracy, resolution down to a few microns (depending on the specifications of the end-user) or integrated vision systems, Universal Robots cobots can automate inspection and quality control tasks in all kinds of environments.

How much does a UR Robot cost?

Generally speaking, a collaborative robot represents an investment in the range of $40,000 to $70,000, but this is a price range to be taken with a grain of salt.

150,000 to $250,000

the price of the entire cell

In comparison, the integration of industrial robots costs about 10 times more.

40,000 to $70,000

the acquisition of a collaborative robot

The most important point for the buyer is to distinguish between the price of the cobot and the price of the entire robot cell. Depending on the complexity of the project, the retrofit required, the resources deployed in integration and the process to be automated, the total cost can vary between $150,000 and $250,000.

10 TIMES MORE EXPENSIVE

the integration of industrial robots

Ready to automate your tasks with Robotiq products?

Think you have an interesting project?

Address

100 Goyer Street, room 103

La Prairie (QC)

J5R 5G5

Phone

514.745.1987

1.800.361.1684

info@pneumac.qc.ca