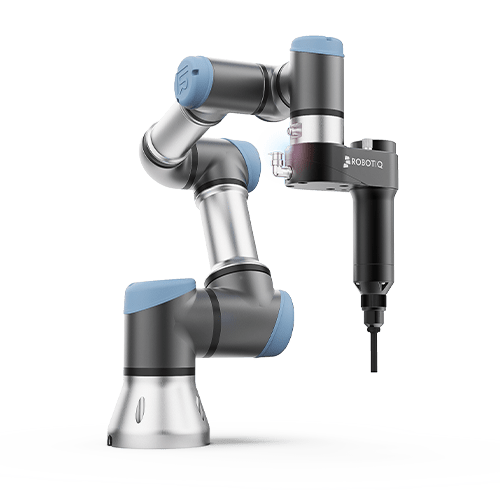

Screwing solutions

Production changes in 5 minutes

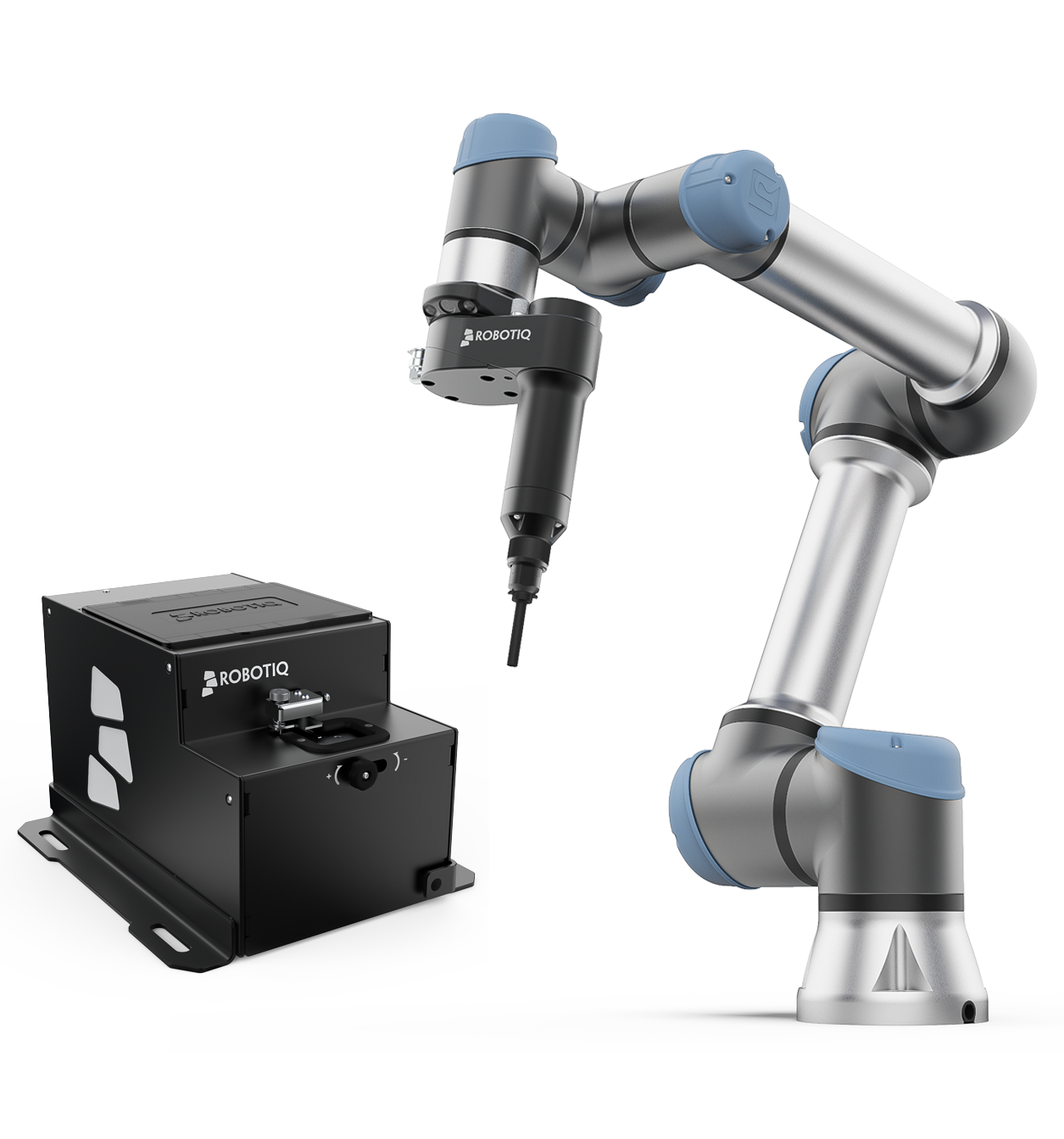

The Robotiq screwdriving solution is designed to solve production changeover problems. In just 5 minutes, the solution can be reconfigured for another production run.

Intuitive deployment

Deploy and control your robotic screwdriving application by integrating the Robotiq screwdriving solution with a collaborative robot. This solution is so simple that no robotics experience is necessary.

Constant screwing in continuous operation

Say goodbye to product recalls and assembly line downtime. Increase your throughput with a reliable and efficient solution.

Fewer injuries and happier staff

When you automate a screwdriving task, you protect your employees from risk and enable them to redirect their attention to value-added tasks. Make them happier!

Configure your application in minutes

Robotiq's URCap screwdriving software simplifies programming, as it automates force sensing capabilities, as well as communication between screwdriver, screw feeder, robot and vacuum technology.

Ready to automate your tasks with Robotiq products?

Think you have an interesting project?