UR20

SCOPE

1750 mm / 68.9 in

USEFUL LOAD

20 kg / 44 lbs

FOOTPRINT

245 mm / 9.6 in

WEIGHT

64 kg / 141 lbs

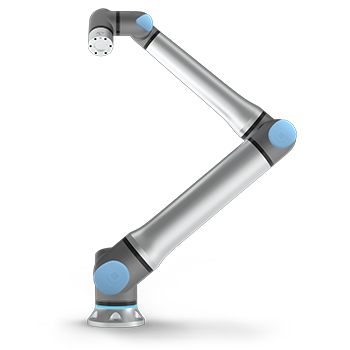

THE COBOT RETHOUGHT

With a reach of 1,750 mm and a payload capacity of 20 kg, the new-generation UR cobot handles more tasks and adapts to more applications. It contributes to production in more varied environments than ever before.

The UR20 is the first model in the new generation of industrial cobots from Universal Robots, designed to take performance to new heights without sacrificing the fundamental qualities of UR cobots: versatility, ease of use and small footprint.

Up to 65% speed gain depending on the joints

25% increase in joint torque capacity

New joint architecture reduces stress on arm mechanics

DESIGNED TODAY, READY FOR THE FUTURE.

The UR20 has been completely rethought, redesigned and rebuilt. Every detail, from the software to the protective covers, has been specially designed to deliver unrivalled performance and quality, so you can increase throughput and uptime to bring even more products to market, faster than ever.

The UR20 is designed for heavier payloads, increased speeds and improved motion control, all in a lightweight system with a reduced mounting footprint for optimum versatility in your existing production space. No need for special electrical connections or costly wiring solutions. Despite the considerable increase in performance, a standard single-phase socket outlet is all that's needed to power the UR20.

Download for free

our complete guide to collaborative robots

THINKING BIG FOR A BIG REACH.

The increased reach extends automation possibilities and efficiency gains to more demanding and heavier applications.

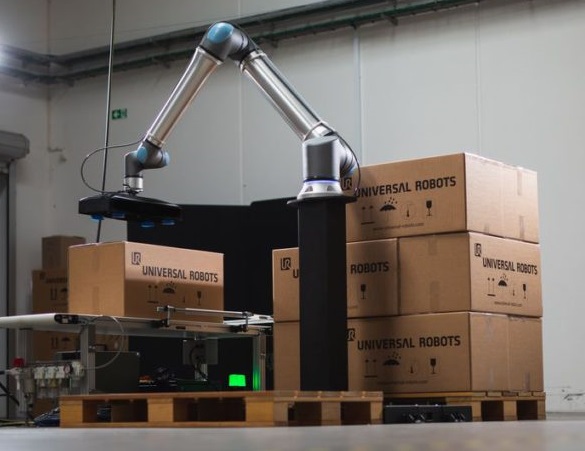

PACKAGING AND PALLETIZING

- Where pick & place, packing and palletizing of heavy parts are required, the UR20 can help companies to increase efficiency and productivity. The UR20 has a reach to match standard europallets, and can stack up to 2 m high.

MACHINE TOOL LOADING

- The UR20 offers great flexibility for handling a wide range of bulky machine parts in applications such as cutting, punching, drilling, machining and forming. As it can be mounted in any position, the UR20 moves effortlessly around workspace elements such as machine tool doors.

PERFORMANCE ON A WHOLE NEW SCALE.

Completely redesigned, the software brings unprecedented trajectory control capabilities, offering 65% more speed and 25% more torque to fully encapsulated articulations.

PARTS HANDLING AND ASSEMBLY

- A larger payload means that heavier parts can be handled, and that multiple tools can be set up and used at the same time, for even shorter cycle times. The manufacture and assembly of bulky equipment, such as engines, vehicle transmission components and battery assemblies, often requires collaboration between human and robot.

WELDING

- In applications typically requiring long weld seams on parts and components, the UR20's small footprint means that several robots can be used in the same production cell. The new joint architecture enhances the fluidity of movements, while the 1,750 mm reach extends your work area.

AUTOMATE ORDINARY MANUAL TASKS

Repetitive tasks with no particular added value detract from operators' concentration, increasing the risk of errors and, in turn, part defects and delays in production schedules.

PROTECT YOUR STAFF

If we look at the top five causes of workplace injury in manufacturing, 8% are due to repetitive movements and 24% to overexertion. The UR20 can now automate more of the most arduous tasks, so that your teams can be redeployed on higher value-added operations.

TRANSFERABLE EXPERTISE

Node-based programs provide a visual representation of operation steps, making them easy to understand and optimize. The productivity of large-scale applications and installations can be maintained despite manpower shortages.

READY FOR THE FUTURE

Easily create, modify, save and transfer programs to suit the task in hand. Optimize without downtime by analyzing and improving programs as they run.

Ready to automate your tasks with Universal Robots products?

Think you have an interesting project?