In a constantly evolving industrial world, process automation is becoming a major challenge for increasing productivity and reducing costs. Among the most significant innovations in this field, Robotiq's palletizing solutions stand out for their efficiency, flexibility and accessibility. This article explores how Robotiq's palletizing solutions are transforming the industrial automation landscape.

Introducing Robotiq

Robotiq, an innovative robotics company, has established itself as a leader in the design of automation solutions for industry. Founded with the vision of simplifying industrial robotics, Robotiq offers a range of products that enable companies of all sizes to easily implement robotic solutions.

Designed to meet the specific requirements of palletizing, you'll enjoy peace of mind when you install and use the low-risk Robotiq Palletizing Solution. The solutions are based on best practice and have been extensively tested, guaranteeing reliability and a rapid return on investment.

The palletizing solution is designed to make automation accessible. Whatever your expertise in robotics, you can master your robot with confidence.

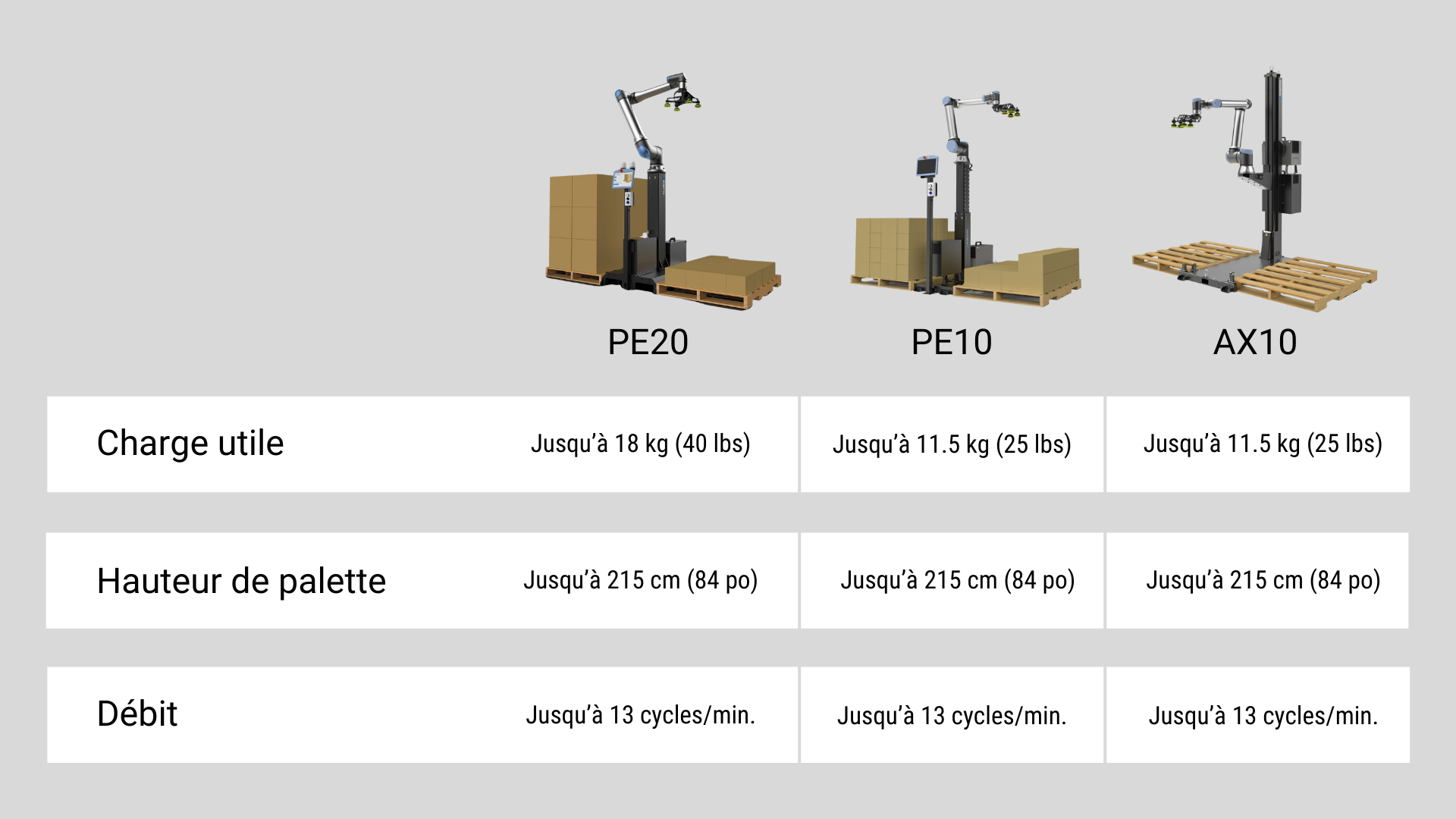

Ideal for heavier loads and moderate pallet heights.

Ideal for light loads and small pallets.

Ideal for a wide range of pallet heights and light loads.

Robotiq Palletizing Solutions

- Flexibility and adaptability: Robotiq palletizing systems are designed to be flexible and adaptable to a variety of production environments. They can be easily reprogrammed for new palletizing patterns, making them ideal for companies with variable production requirements.

- Ease of integration: One of the major advantages of Robotiq solutions is their ease of integration into existing production lines. They are compatible with a wide range of industrial robots, enabling smooth integration and reducing downtime.

- Intuitive user interface: Robotiq makes a point of making its systems accessible, even to operators with no previous robotics experience. User interfaces are designed to be intuitive, simplifying programming and handling of palletizing systems.

- Space optimization: Robotiq solutions are designed to maximize the use of factory space. Their compact design allows them to be integrated into tight spaces, optimizing available production space.

- Improved productivity and safety: By automating the palletizing process, Robotiq solutions reduce the manual workload, minimizing human error and improving workplace safety. This translates into increased productivity and reduced costs associated with injuries and worker fatigue.

Setting up your job is simple and requires just three steps