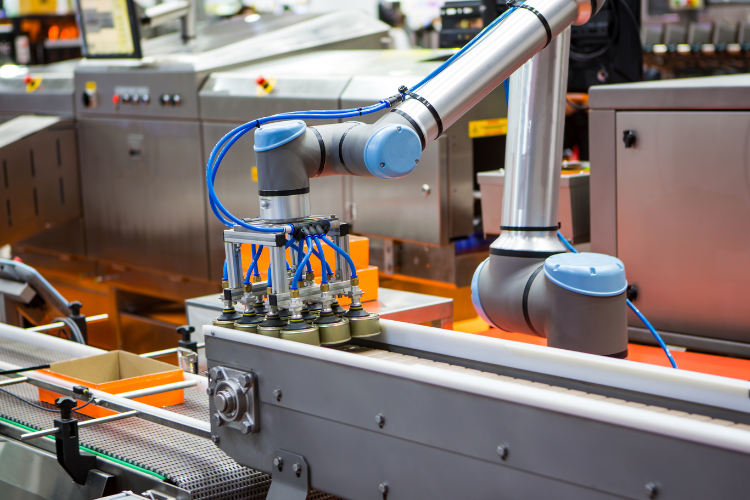

Selecting the right suction pad for your application is essential for optimum performance and efficiency.

When it comes to maximizing efficiency and performance in industrial applications, choosing the right suction cup is a crucial element that is often underestimated. This seemingly simple part plays a vital role in a multitude of processes, from the delicate handling of fragile products to the quick and safe management of heavy or bulky materials. In this article, we'll explore the essential factors to consider when selecting the perfect suction pad for your application. Whether handling food products, assembling electronic components, or handling automotive parts, every aspect, from surface texture to object shape, influences the choice of the ideal suction pad. We'll provide you with detailed information on each key factor, from consideration of material and surface texture, to analysis of object shape and size, operating environment and durability. This article will help you understand how to optimize the performance and durability of your tools, while taking energy consumption and cost into account, to ensure an informed selection tailored to your specific needs.

1- Surface material and texture

The performance of a suction pad is highly dependent on the surface with which it interacts. For example, smooth, non-porous surfaces require different suction cups to those needed for rough or porous surfaces. Piab's MX suction pad, with its advanced design, is able to handle a variety of surfaces, from the smoothest to the most irregular, ensuring a safe and effective grip.

MX Suction Cup family - the #1 item picker

2- Object shape and size

The geometry of the object is crucial. Flat objects will require different suction cups to those needed for rounded or irregularly shaped objects. Deep concave suction pads, for example, are ideal for gripping domed or curved objects, as they can conform to the shape of the object and ensure a better grip.

3- Levy rates

The speed at which objects need to be handled is an essential factor. If your process requires a high pick rate, you need a suction cup that can react quickly while maintaining a secure grip. Piab's MX is designed for dynamic handling, which means it can handle fast movements while maintaining a good grip on the object.

4- Environment

Thechoice of suction pad depends on theoperating environment. In sensitive environments such as the food industry, it's crucial to use suction cups that won't contaminate products. Materials approved by Health Canada, the FDA and the EU are essential to guarantee safety in these environments.

5- Energy consumption

Energy efficiency is becoming increasingly important in the industrial world. Vacuum cups like Piab's MX, designed to minimize energy consumption, can help reduce operating costs and the ecological footprint of your production process.

6- Durability and longevity

The service life of a suction pad depends on the quality of its materials. Suction pads made from DURAFLEX®, for example, offer a unique combination of flexibility and wear resistance, making them ideal for applications where durability is a key concern.

7- Cost

While the initial price is a factor to consider, it's also important to look at the total cost of ownership. More expensive suction pads like Piab's MX can offer better long-term value by reducing maintenance requirements and increasing process efficiency.

Don't forget that real-life testing is crucial. We can help you select the suction pad best suited to your specific needs, offering you a tailor-made solution that optimizes performance and efficiency.

Ready to choose your suction cup?

Do you need advice?