Achieving maximum yield from agricultural production is a key objective for an agricultural sector tasked with feeding a growing world population, while operating as sustainably and economically as possible.

Robust, precise, flexible and connected process control solutions play a key role in supporting the innovative approaches needed for a successful future in food production.

Process control technologies from Norgren are supporting two major projects in Singapore and the United States. They highlight alternative approaches to the challenges of food security and more efficient agriculture through better use of resources.

Better control for operational efficiencies

Singapore-based Agri-Tech, Singrow, is at the forefront of the search for answers to the persistent problems of food security and efficient, sustainable crop production. And its unique genome and precision farming platform efficiently cultivates, grows and distributes products such as climate-resistant strawberries under controlled conditions.

Norgren has worked with Singrow to help it achieve operational efficiencies such as significant energy savings, and to support and drive sustainable operations that optimize the use of valuable resources such as water and energy.

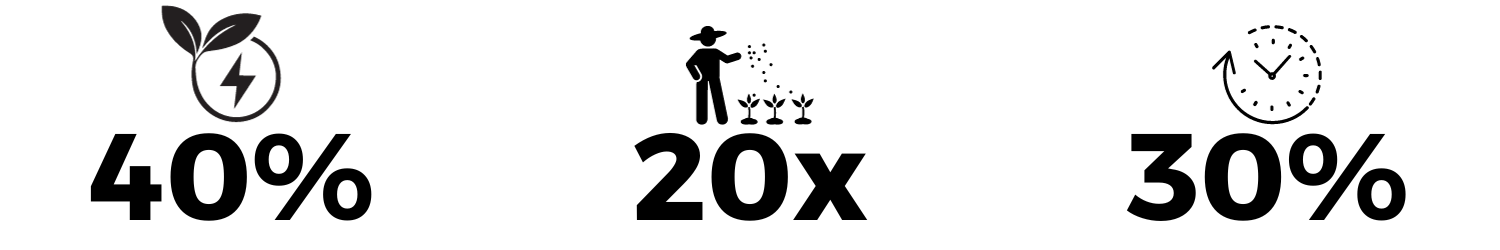

Thanks to innovative control technology, visualization tools and system connectivity that supervise irrigation, lighting and ventilation functions, Singrow benefits from a substantial 40% reduction in energy consumption, a 20x increase in crop yield and 30% less production time.

24/7 precision thanks to Norgren's intelligent technology

Norgren's state-of-the-art technology, including multimedia digital valves, intelligent sensors and data acquisition, has enabled Singrow to provide continuous monitoring and control for better optimization of resources. Buschjost's solenoid valves precisely regulate irrigation to ensure a constant supply of water and nutrients to the strawberry crop. The intelligent control system automates light and ventilation, ensuring ideal growing conditions. Overall, the technology intelligence-based system improves critical processes, assisting operations around the clock as part of Singrow's vertical farming for maximum productivity.

Optimized light and ventilation for crop growth

The intelligent control system optimizes crop growth by automating the supply of artificial light and precision ventilation for Singrow. The system ensures that crops receive the ideal amount of light for their growth needs, and saves energy by switching off when not required. In addition, intelligent ventilation control maintains standardized conditions, promoting an optimal environment for growing crops. This technology improves agricultural sustainability and productivity.

Data-driven agriculture

The automated connectivity control system ensures the real-time availability of intelligence-based data to guide Singrow's decision-making. Norgren Edge Computing capability enables Singrow's farming operations to be managed remotely via mobile devices, simplifying daily tasks and maximizing crop productivity. Constant feedback ensures that the optimum conditions are in place for a productive and efficient yield/cost ratio.

Innovative companies such as Singrow are at the forefront of the global food-producing community's response to increasing food safety risks. Its unique vertical farming methods are delivering tangible results, and Norgren is playing its part in helping the company sustainably optimize its day-to-day performance.

Raven - Helps maximize crop yields.

Norgren has been working with Raven for a decade. The company designs, develops and manufactures precision agricultural spraying systems as part of its portfolio of solutions that deliver advanced agriculture through technology and innovation.

Raven's systems offer a variety of technologies enabling farmers to maximize yields and return on investment by, for example, reducing costly fertilizer or pesticide spraying to cut costs and better protect the environment.

A recently launched spray system, the 'Hawkeye 2', uses Norgren's valve technology to provide precise, reliable and robust control for the nozzle bodies that dispense the product onto the field.

There can be between 70 and 140 nozzle bodies on a single spray boom, and each nozzle incorporates a Norgren solenoid valve. The valve provides control to the pulse-width modulation solution, which acts to ensure that different fertilizers, pesticides and other media are sprayed quickly and evenly, so that they are accurately distributed to crops when and where needed.

The products used in agricultural spray systems are expensive to buy, and any reduction in waste, as only essential crop areas are treated, offers an economic benefit to farmers and lower levels of unnecessary chemicals entering the soil.

Valve control extends to modulating individual nozzle outputs to take account of tractor turning maneuvers when one end of the spray boom needs to distribute media faster than the other.

Having to work in harsh environments, subject to strong tractor and landscape vibrations and handling a variety of difficult media, the Norgren valve's proven reliability offers tangible operational benefits to farmers who need to trust the spray system to avoid unwanted, inconvenient and costly spray stoppages.

Norgren's work with Singrow and Raven are examples where innovative, connected control solutions deliver tangible sustainability benefits, helping customers to make informed decisions and improve operational efficiency. Consumption of resources, energy and chemicals is reduced, costs are saved and, efforts to increase food production for the benefit of all, are sustained."

Would you like to find out more about Norgren solutions?