Let's explore how SMEs can take advantage of collaborative robots to improve efficiency, cut costs and boost competitiveness.

Collaborative robotics, or cobotics, has emerged as a transformative solution for the industrial sector, bringing significant benefits to large companies and SMEs alike. Unlike traditional automation systems, which often require specific and costly infrastructures, collaborative robots are designed to work alongside human employees in a variety of work environments. This article explores in depth the benefits of collaborative robotics for small and medium-sized businesses, highlighting how these technologies can optimize operations, reduce costs and improve product quality.

Flexibility and adaptability

One of the main advantages of collaborative robots for SMEs is their flexibility. Unlike traditional industrial robots, which are often specialized in specific tasks and require substantial modifications to change function, collaborative robots are designed to be versatile. Their ability to be rapidly reconfigured enables companies to adapt to fluctuations in demand, diversify production and respond effectively to changing market needs.

For example, an SME specializing in the manufacture of electronic components might use a collaborative robot to assemble parts during a period of high demand. Once demand is reduced, the same robot can be reprogrammed to carry out different tasks, such as packaging or quality control, without the need for major new investment.

Cost reduction

Collaborative robots also offer a cost-effective solution for SMEs. Their acquisition cost is often lower than that of traditional industrial robots, largely because they are designed to be more accessible and less complex to install. In addition, maintenance and training costs are generally lower, reducing overall expenses for the company.

By integrating collaborative robots, SMEs can also reduce the costs associated with human error and production stoppages. Robots can perform tasks with consistent precision, minimizing waste and production defects. As a result, savings in production costs and improvements in product quality can more than offset the initial investment in the technology.

Improving Quality and Accuracy

Collaborative robots are designed to perform tasks with a high level of precision and repeatability. This ability to perform complex operations consistently helps to improve product quality. For SMEs, this means fewer defects and product returns, which can improve customer satisfaction and enhance the company's reputation.

Take the example of an SME specializing in the production of metal parts. A collaborative robot can be used to weld components with millimetric precision, reducing quality deviations that might otherwise lead to rejections or costly rework. By improving the precision of the manufacturing process, SMEs can offer better quality products to their customers, which can translate into increased sales and market share.

Production Process Optimization

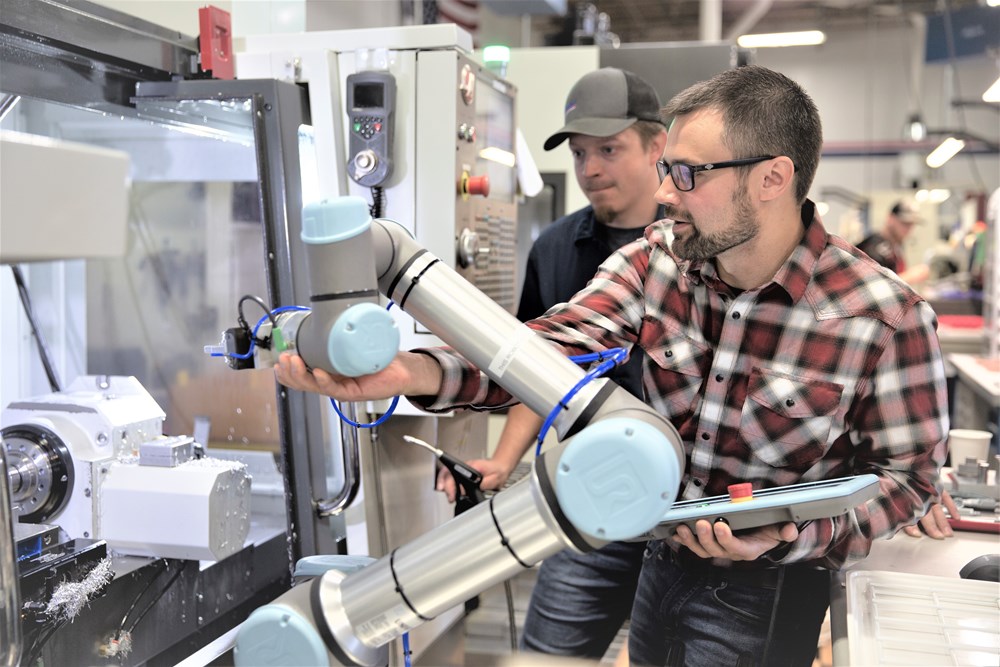

Collaborative robots also enable significant optimization of production processes. Working alongside human operators, these robots can take on repetitive, hazardous or ergonomically challenging tasks. This enables workers to concentrate on more complex, value-added activities, which can improve overall production efficiency.

For example, in a packaging production line, a collaborative robot may be in charge of automated product packaging, while human employees focus on quality control and inventory management. This division of labor not only speeds up the production process, but also enhances employee safety and comfort.

Easy to integrate and use

Unlike traditional automation systems, collaborative robots are designed to be easily integrated into existing work environments. They are generally quick to install, and do not require major infrastructure modifications. What's more, most collaborative robots feature intuitive user interfaces that enable employees to program and control them without advanced technical skills.

This ease of integration is particularly beneficial for SMEs that do not have the resources to invest in complex infrastructures or to train their staff in sophisticated technologies. Collaborative robots often come with accessible training programs and technical support to facilitate their adoption and day-to-day use.

Strengthening Innovation and Competitiveness

The integration of collaborative robotics also enables SMEs to remain competitive in a constantly evolving market. By adopting advanced technologies, companies can improve their agility, capacity for innovation and responsiveness to new market trends. This can offer a significant competitive advantage, enabling SMEs to launch new products more quickly, meet customer needs more efficiently and seize new business opportunities.

Conclusion

Collaborative robotics offer valuable benefits to small and medium-sized businesses by improving flexibility, reducing costs, increasing precision, optimizing production processes and facilitating integration. By taking advantage of cobotics technologies, SMEs can modernize their operations, improve product quality and boost their competitiveness in the marketplace. For companies looking for innovative solutions that combine efficiency and accessibility, collaborative robotics is a strategic and promising option.

Do you need advice?