An overview of the latest technological advances in collaborative robotics and how they could shape the future of various industrial sectors.

Recent innovations in Collaborative Robotics: What lies ahead?

Collaborative robotics, or cobotics, is booming, transforming working environments through cutting-edge technological innovations. Collaborative robots, designed to work alongside humans safely and efficiently, continue to evolve, offering more flexible, intelligent and accessible solutions. This article explores recent innovations in collaborative robotics and examines what these advances could mean for the future of industry and work.

Next-generation collaborative robots: towards greater flexibility and intelligence

Modern collaborative robots are no longer content to repeat simple tasks. Recent innovations enable cobots to perform increasingly complex tasks with great precision. This evolution is made possible by significant improvements in design, programming and artificial intelligence.

Advances :

- Advanced Vision Technology: The new cobots are equipped with sophisticated vision systems that enable them to detect and interact with their environment more precisely. These systems can identify objects, perform quality checks and guide robots in dynamic environments.

- Machine learning algorithms: cobots incorporate machine learning algorithms that enable them to adapt and learn new tasks with minimal human intervention. This enhances their flexibility and ability to adjust to a variety of processes.

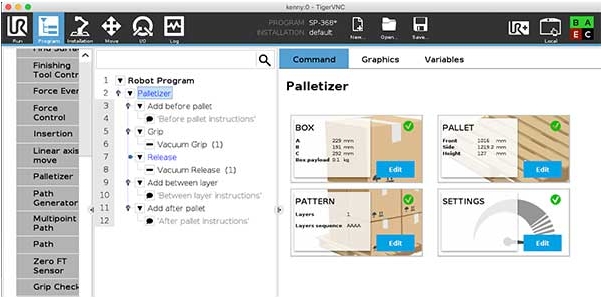

Improved user interface: simplified programming

One of the major barriers to the adoption of collaborative robots has been their complex programming. However, recent innovations have simplified this process, making cobots more accessible to non-expert users.

Advances :

- Tactile and intuitive interfaces: New programming tools with tactile interfaces enable users to program cobots using simple graphical interfaces. This reduces the need for specialized programming skills.

- Visual Programming Language: Visual programming languages, such as building blocks or flow charts, make it easy to configure robot tasks and movements without the need for complex code.

Improved safety: Working hand in hand with Humans

Safety is a major concern when it comes to collaborative robots working in close proximity to humans. Recent innovations focus on creating safer working environments while improving cobot performance.

Advances :

- Detection sensors: cobots are now equipped with advanced detection sensors that can identify the presence and movement of people around them. These sensors enable robots to react quickly to avoid collisions and guarantee a safe working environment.

- Soft materials and shock absorbers: The use of soft materials and shock absorbers in the construction of cobots reduces the risk of injury in the event of accidental contact with human operators. These features enable cobots to work closer to humans while minimizing risk.

Integrating the Internet of Things (IoT): Connected collaboration

The integration of the Internet of Things (IoT) into collaborative robotics is opening up new opportunities for connected, intelligent collaboration. Cobots can now communicate with other equipment and systems, improving the efficiency of production processes.

Advances :

- Real-time communication: cobots can exchange data in real time with other machines and production management systems. This enables more precise coordination and faster response to changes in the working environment.

- Predictive maintenance: thanks to IoT, cobots can monitor their own status and signal maintenance needs before a breakdown occurs. This reduces downtime and extends equipment life.

Diversified applications: From manufacturing to healthcare

Recent innovations in collaborative robotics have broadened the scope of cobots, making them useful in a variety of sectors beyond traditional manufacturing. These robots are now used in a variety of environments, bringing specific benefits to each field.

Advances :

- Healthcare: Cobots are used for tasks such as assisting in surgical procedures, handling samples and supporting patient care. Their precision and ability to work closely with healthcare professionals improve care outcomes.

- Logistics sector: In warehouses and distribution centers, cobots help with inventory management, order picking and parcel handling. Their flexibility and ability to adapt to a variety of tasks optimize logistics operations.

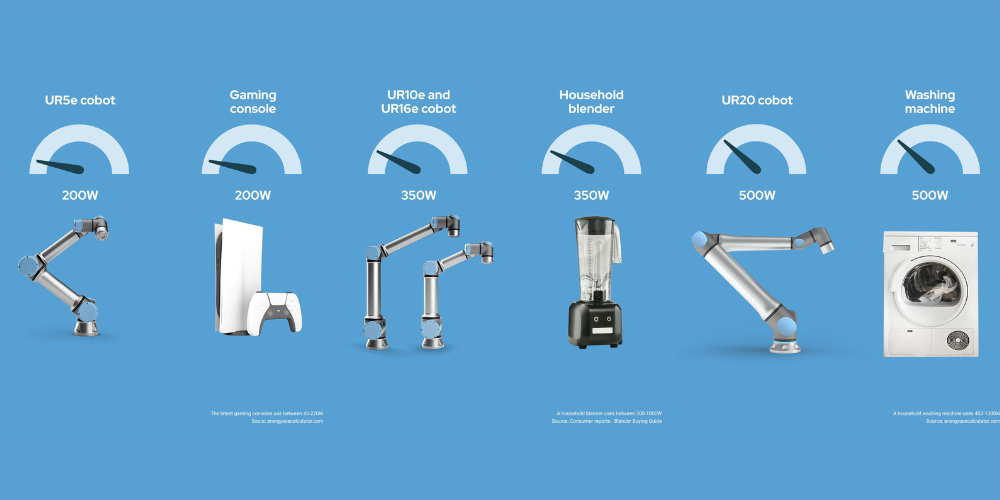

Sustainability and energy efficiency: A greener future

Sustainability is another area of innovation in collaborative robotics. Cobot manufacturers are working on greener, more energy-efficient solutions to meet growing environmental concerns.

Advances :

- Environmentally-friendly design: the new cobots are designed using recyclable materials and more environmentally-friendly manufacturing processes. This reduces the carbon footprint of robot production.

- Energy efficiency: Improvements in the energy efficiency of cobots reduce their energy consumption while maintaining high performance. Integrated energy management systems optimize resource use and reduce operating costs.

Conclusion

Recent innovations in collaborative robotics are paving the way for a future where robots work even more closely and effectively with humans. Advances in flexibility, safety, programming and connectivity are transforming working environments, making cobots more intelligent, accessible and suitable for a variety of applications. As these technologies continue to evolve, they promise to redefine the way we work and interact with machines, bringing significant benefits in terms of productivity, safety and sustainability.

Do you need advice?